Among the many factors to consider when specifying and selecting products for your home envelope is time. As in, how much time will the wall system likely be exposed before the cladding and trim are installed? Because ultraviolet rays can affect the long-term performance of the home’s housewrap and flashing, it’s important to anticipate and accommodate longer-than-normal UV exposure times.

Why is UV Exposure a Concern for Wall Systems?

UV rays can impact building materials in many ways, and housewrap is no exception. Long-term UV exposure can break down the protective control layer of a weather resistive barrier (WRB). These issues mean the WRB won’t perform as it’s designed, possibly compromising the home’s water holdout and failing prematurely.

In fact, leaving your housewrap exposed for too long could void the product’s warranty.

What Factors Impact Housewrap’s UV exposure?

Most traditional WRBs come with a manufacturer recommendation for UV exposure that should accommodate most typical build schedules. For example, FlatWrap HP and HydroGap SA are both rated for a maximum of 120 days of UV exposure.

For normal-size production homes, scheduling and supply challenges are the most likely culprits for longer-than-anticipated exposure, including unforeseen delays in receiving materials or last-minute changes in siding selection. Labor or scheduling hurdles with subcontractor crews also may play a role.

For larger and custom homes or multifamily projects, the inherent size and lengthier schedule may cause the WRB to be exposed for longer than it is on smaller, simpler houses. This is a more common occurrence that often can be determined and planned for in advance.

How to Avoid UV Concerns with Housewrap

For residential projects, scheduling is the most important factor in avoiding the housewrap’s exposure to UV rays past what the manufacturer recommends. The exterior shouldn’t be dried in with the housewrap until the siding selections and delivery are confirmed. In addition, subcontractors should be scheduled accordingly. This includes ensuring other trades remain on time to avoid getting in the way of the siding installers when the time comes.

For projects more likely to encounter a longer period of time from drying-in to cladding installation, specifiers should err on the side of caution and use WRB and flashing products designed and tested to withstand longer UV exposure.

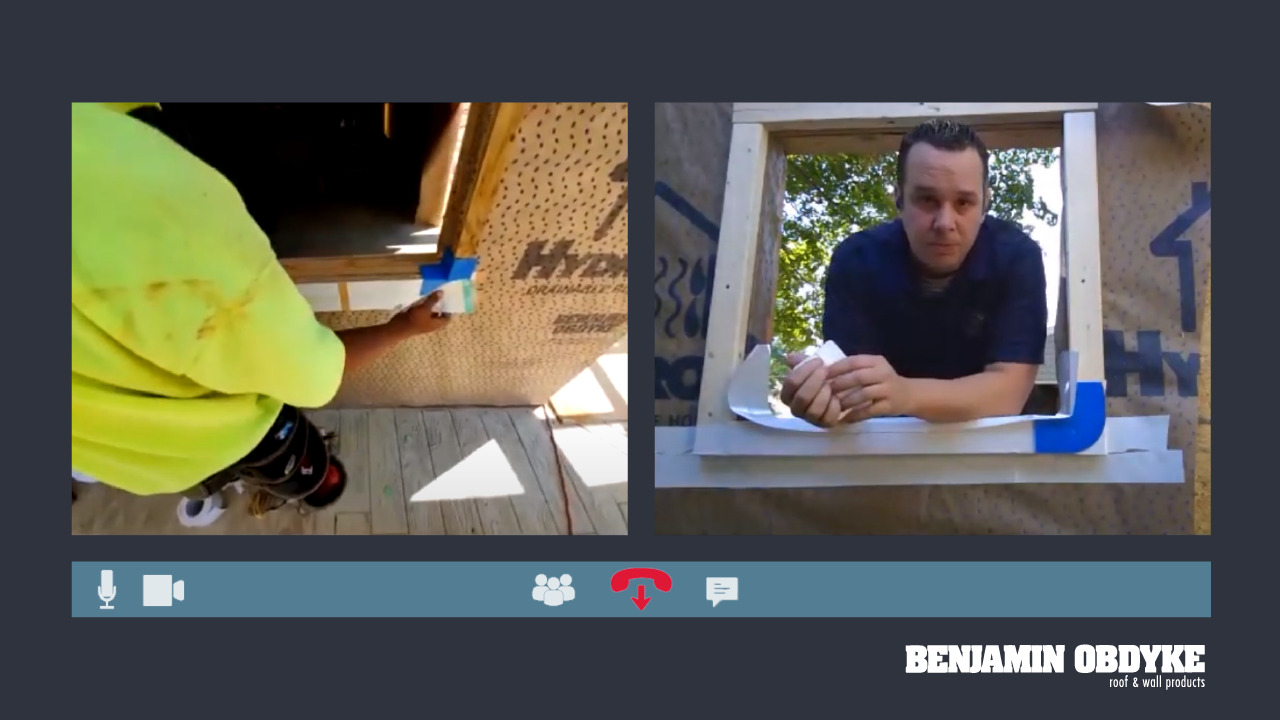

For example, InvisiWrap UV is a black housewrap that allows for 12 months of UV exposure, making it suitable for open-joint cladding (where larger gaps in the siding will expose the housewrap to more UV rays than normal) or for projects where the WRB will be left uncovered for a longer period of time. This not only makes it ideal for large custom homes but also light commercial projects.

Complementing InvisiWrap UV for these types of projects, HydroFlash UV+ is a UV-stable tape that also carries a 12-month UV rating. Its acrylic adhesive is formulated for extreme environmental conditions.

If projects that don’t have these products encounter delays, installers should cover the wall assemblies with another material until the siding installation is ready.

Order a sample of InvisiWrap UV and HydroFlash UV+ today and ensure your assembly is safe from UV exposure.