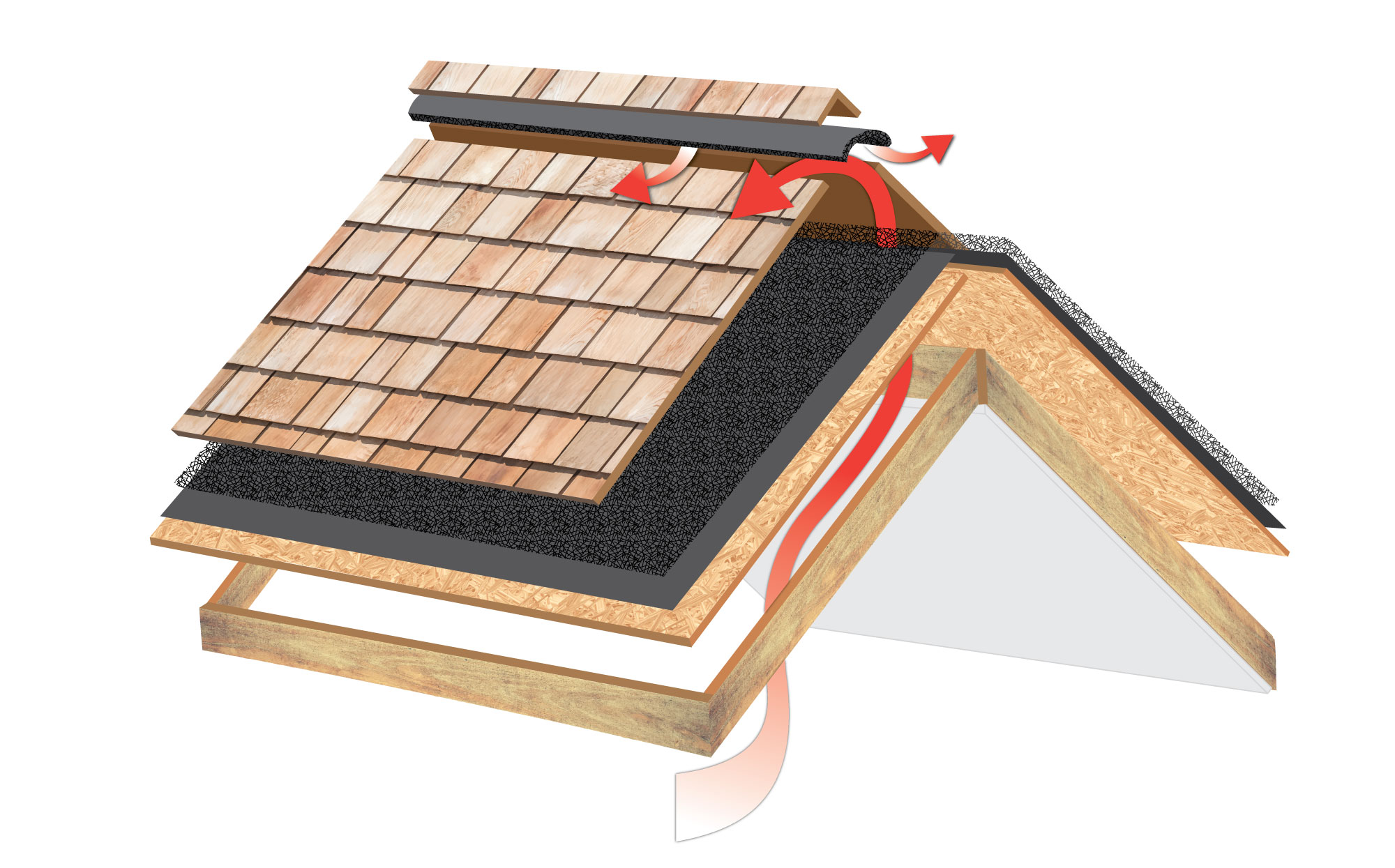

A rainscreen, like our Slicker products, is essentially a 1/4-to-3/4-inch air gap built in-between the the exterior siding and sheathing of a wall assembly. When combined with a WRB, a rainscreen is designed to reduce the forces that draw water into the your sheathing. Water that does reach the back of the cladding or siding is permitted to drain from the wall assembly via the space created.

Slicker® Rainscreen Samples

GET YOUR FREE SLICKER® RAINSCREEN SAMPLES TODAY

This kind of moisture management product offers accelerated drying of water vapor that accumulates in-between the siding and sheathing by moving air in a convective fashion throughout the wall air gap provided. Both the top and bottom of the cavity also should be ventilated to allow moisture to escape and in- crease the drying rate. Proper detailed flashings around all penetrations are also critical to the success of the system.

The traditional method of constructing a rainscreen is by nailing wood or plastic furring strips – also called strapping – over wall studs and sheathing after applying a building paper or housewrap. However, installing these wood or plastic strips is labor-intensive and therefore strapping is more costly than using a manufactured rolled rainscreen. Other drawbacks of strapping include the creation of hot spots along stud locations and trapped moisture as a function of wood-to-wood contact, which can lead to reduced air movement and a greater potential for mold buildup and rot.

Whether you’re looking for rainscreen for siding, masonry, or an open joint system – we offer three solutions ready to get you started: Max, HP and Classic. Check out the video below for more information on our Slicker product line.