As homes become tighter and more energy efficient, the changes in design may unintendedly impact other areas of the home—and the roof is one of those places. Conditioned attics are an increasingly popular option for homes to increase energy efficiency. Unfortunately, they often are not designed with proper vapor permeability nor adequate ventilation in mind, which can lead to condensation and mold.

Here’s what to know about vapor permeability and modern roof systems.

Why is Vapor Permeability in Roofing Systems Important Today?

Understanding the vapor profile of a roof or wall assembly is more important as we increase homes’ air tightness and thermal resistance. In the past, homes had less insulation and poor air barriers, which allowed heat and water vapor to move freely through the assembly. Roof ventilation was once enough to remove excess moisture from the attic space.

However, builders are increasingly moving to conditioned, well-sealed attic spaces with mechanical systems to create a consistent environment. A side effect of this trend is an accumulation of interior water vapor that rises as the warm air rises toward the roof peak. With traditional vapor-closed underlayments, such as ice and water shield products, this water vapor cannot escape, leading to high moisture content in the roof sheathing that can contribute to rot and failure, reducing the life span of the roof assembly.

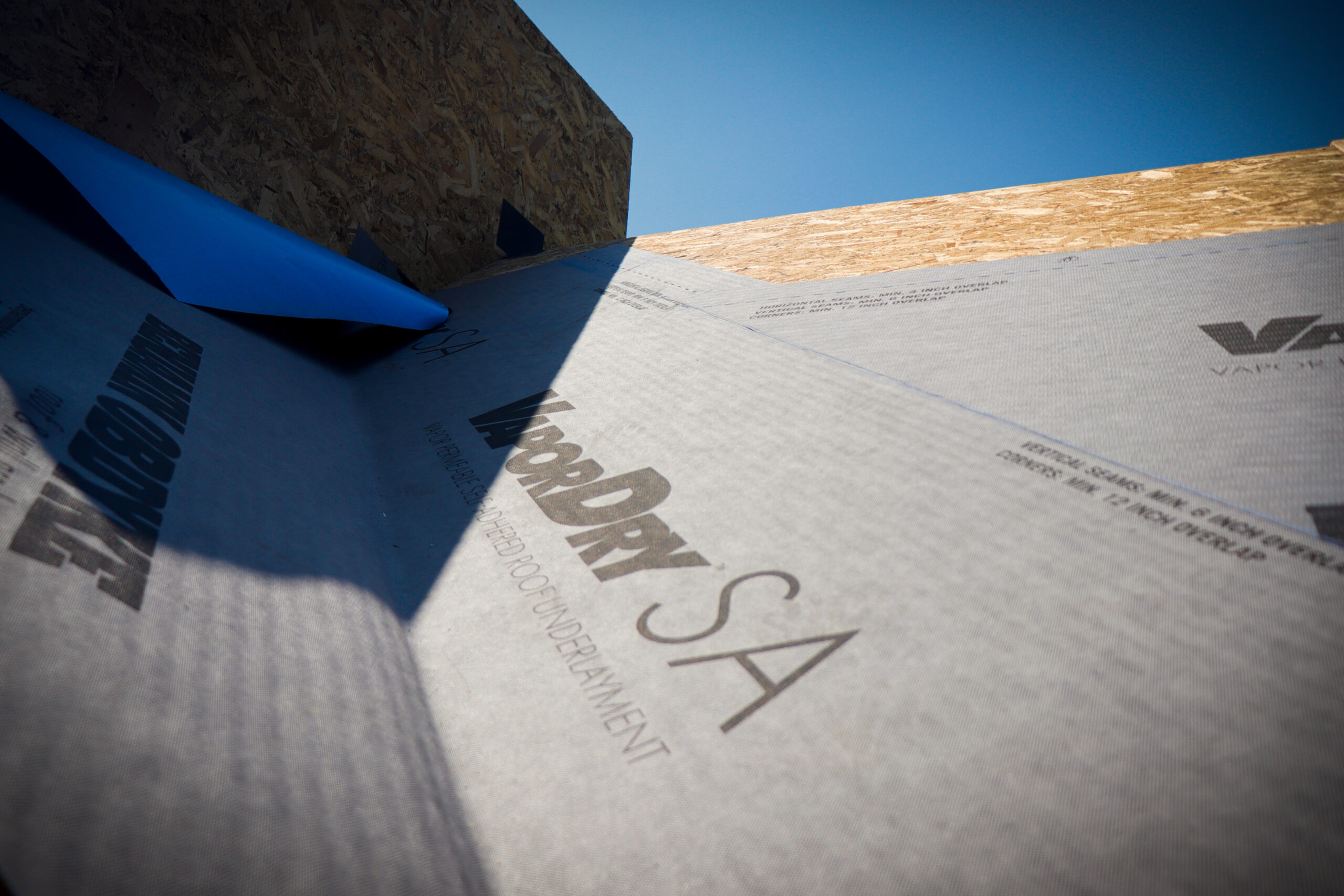

VaporDry® SA Samples

GET YOUR FREE VAPORDRY® SA SAMPLES TODAY

How to Incorporate Vapor Permeability in Roofing Systems

For roofing systems above conditioned attics, a vapor permeable roofing membrane such as VaporDry SA allows water vapor from the attic to migrate, increasing drying potential to reduce the likelihood of long-term issues. In addition, VaporDry SA has a continuous acrylic adhesive that self-seals around roofing fasteners, allowing the membrane to serve as an air-control layer in addition to a moisture-control layer.

To maximize the drying potential of VaporDry SA, create an air gap between the bottom of the cedar or metal roofing and the underlayment by installing Cedar Breather in between. This will provide maximum drying potential. Asphalt shingles can be installed directly over VaporDry SA.

VaporDry SA meets ASTM D1970 testing standards for nail sealability and ICC-ES AC48 for Self-Adhered Underlayments to be used as an ice barrier, and it can be left exposed for 120 days.

Learn more about VaporDry SA or get in touch with us for support and resources to help Transform Your Craft.