One of the most essential parts of a well-designed wall system is a drainage plane that allows bulk water that breaches the cladding to drain away and also provides airflow to dry out the cavity. That drainage plane is typically created in one of two ways: via a rainscreen or a drainable housewrap. Understanding the differences between the two, and which is most suited for each project, can help ensure you make the right productselections—and ultimately create a wall system that lasts.

The Wall System

High-performing walls perform best as a system, so simply swapping out one product type for another could cause the envelope to fail or not live up to its potential. If a project specifies a rainscreen, for example, switching it out for a drainable housewrap under the assumption that it will do the same thing isn’t advised without examining the potential impact on the other products in the system.

Think of the drainage plane in a good-better-best scenario: A flat housewrap is good, a drainable housewrap is better, and a rainscreen is best. The primary difference is the volume of bulk water than can drain away and the amount of air that can move through the system to effectively rid it of moisture.

A rainscreen is the more robust of the options and can be created by attaching furring strips to the housewrap and sheathing or with a roll-on 3-D matrix material such as Benjamin Obdyke’s Slicker or Slicker HP. Some claddings have rainscreens built into the backside of the material. The rainscreen creates a capillary break that causes it to drain downward, and also creates a larger airspace for drying.

Drainable housewraps incorporate spacers onto the face of a traditional wrap, either with an embossed texture or physical bumps. A drainable wrap releases the pressure that builds up to drain but doesn’t increase the wall system’s drying potential.

There are important considerations within the drainable housewrap category, as well. For example, an embossed or textured wrap doesn’t create a true drainage space, causing friction that holds a lot of water. Benjamin Obdyke’s HydroGap and HydroGap SA drainable housewraps have a 1mm space, however, which provides greater drainage efficiency of up to 96%. For these reasons, some siding manufacturers recommend or require certain types or brands of drainable housewraps, so be sure to verify with your siding rep.

Benjamin Obdyke Protection Systems Samples

GET YOUR FREE PROTECTION SYSTEMS SAMPLES TODAY

Product Considerations

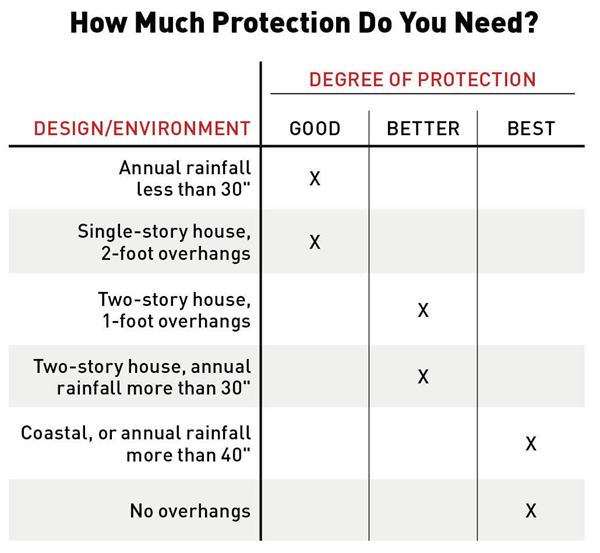

What system you should choose depends on several factors. First is climate: A rainscreen should be one of the first considerations in wetter regions like the Pacific Northwest and the Northeast, but may not be necessary in drier areas.

You’ll also need to weigh budget and cladding. With a tighter budget, a drainable housewrap could be good enough for cladding materials like fiber cement and composites. But a rainscreen is a crucial investment under wood siding and masonry. Rainscreens prolong the life of wood claddings by reducing moisture content and decreasing maintenance needs.

In addition, changes to the 2021 International Residential Code will require a rainscreen behind stucco for projects in geographic areas with at least 20 inches of annual rainfall. Oregon recently adopted a specialty drainage requirement for a 1/8” rainscreen behind cladding; drainable housewraps can be used instead if the product achieves a drainage efficiency over 75%.

Another consideration is the home’s window details. Installing a rainscreen will add at least ¼ inch to the exterior surface; depending on the thickness or projection of the windows, it can impact the appearance of the trim details. Packing out the window to address the extra ¼ inch can in turn influence the interior trim, requiring an extension jamb to ensure the window reaches the drywall layer. If such changes aren’t possible, a drainable housewrap may be an ideal alternative if allowed by the siding manufacturer.

For customized support and insights into these tactics and best practices, Benjamin Obdyke’s team is available for virtual jobsite visits. Sign up here.

Above all, it’s critical to be thinking of the envelope as a system, rather than just focusing on what products might be in stock. Not all materials work with others. Taking a systems approach ensures products are compatible and that together they will collectively prevent moisture and air intrusion into the home. Reach out to your manufacturer and dealer partners to learn more about their systems and how their products integrate with other brands and options.