For most residential wall systems, creating a drainage space is essential—it provides room for moisture to escape and promotes air circulation to dry out the cavity. How much air space is needed depends on a couple of factors, most importantly the cladding type and the local climate. Some cladding materials and homes in dry regions may only need a space provided by a drainable housewrap. Most others require rainscreen systems for optimal performance.

What Are Rainscreen Systems?

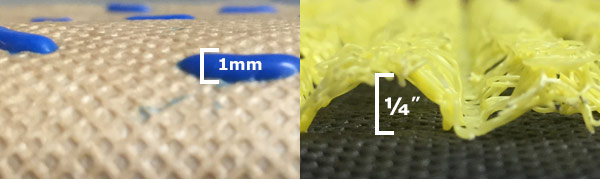

A rainscreen controls rain entry in an exterior wall by creating a pressure-moderated air space between the exterior cladding and the sheathing or weather resistive barrier. The 1/4- to ¾-inch air space reduces the forces that draw water into the building assembly. Any water that does reach the back of the cladding is able to drain from the wall assembly via the space created by the rainscreen. At the same time, a rainscreen offers accelerated drying of moisture-laden air (vapor) that accumulates in the interior wall assembly by moving air in a convective fashion throughout the cavity.

The laws of physics demand that the air space be at least 3/16 inch in depth to provide the necessary capillary break that will prevent water from bridging from the back of the cladding onto the weather resistive barrier’s drainage plane. Both the top and bottom of the cavity should be ventilated to allow moisture to escape and increase the drying rate. Proper detailed flashings around all penetrations are also critical to the success of any moisture management system. (Check out our previous blog post “4 Steps to Properly Seal Wall Penetrations in the Building Envelope.”)

What Are the Different Types of Rainscreen Systems?

Rainscreens generally fall into one of the following categories: furring strips, entangled net matrix, grid systems, and spacing clips and mounting systems.

Furring Strips

Wood furring strips, fastened vertically on top of the sheathing and weather resistive barrier, are the most traditional method for creating a drainage pathway. Furring strips are easy to source. But while they’re relatively lower in material price, they have a slightly higher labor cost.

Wood furring strips also can absorb and transfer moisture, so they’re not as durable long-term as manmade materials, and they can act as a thermal bridge, impacting a home’s energy efficiency.

Batten UV strips, made with polyethylene, offer an alternative. These have the same compression resistance as traditional wood furring strips but won’t absorb moisture or create a thermal bridge. They also have a notched design that provides multi-directional airflow and drainage, unlike solid wood.

Entangled Net Matrix

Net matrix products utilize a “void space” using a 3D plastic matrix to create a vented, continuous rainscreen for greater drainage efficiency. Builders can choose from several different manufactured varieties — a plastic matrix that can be applied directly over a water resistant barrier or special bonded products that combine the plastic matrix with a water resistive barrier for a one-step installation.

A 3D matrix like Slicker Classic or Slicker Max comes on a roll and fastens with a hammer tacker or stapler, so it’s more efficient to install compared to furring strips. There are also no concerns about moisture damage or thermal bridging. Manufactured products have a higher price than wood furring strips and a matrix is more prone to compression during installation.

Want to learn more about net matrix products? Watch this video to learn more about Slicker.

Grid Systems

A grid-style rainscreen fastens with no special tools and is easier and faster to install than furring strips. It has a flexible design and consistent plane that allows for maximum drainage and drying while offering increased compression strength versus a 3D rainscreen matrix.

Space Clips and Mounting Systems

Fastener and clip systems are typically designed for specific cladding materials that require a systems installation approach; while some universal systems exist, they can be tricky to adapt to cladding and require precise installation while offering a narrow margin for error. Clip systems do provide a solution for exterior designs with thicker installation, though these are seen mostly in commercial applications.

Other Considerations for Rainscreen Systems

When choosing rainscreen systems, the first step is to follow instructions from your cladding manufacturer or local code body. Certain materials, such as fiber cement, poly-ash, and manufactured stone, have minimum drainage and/or minimum spacing requirements between the cladding and the wall. Climate also will play a role, as zones with high precipitation or humidity may impact the longevity of wood furring strips.

Wall systems with exterior insulation are best suited to furring strips or clip-style rainscreens, depending on the thickness of the foam board and the need for structural loading. Total wall thickness can impact other variables, as well, such as trim accessories and window framing.

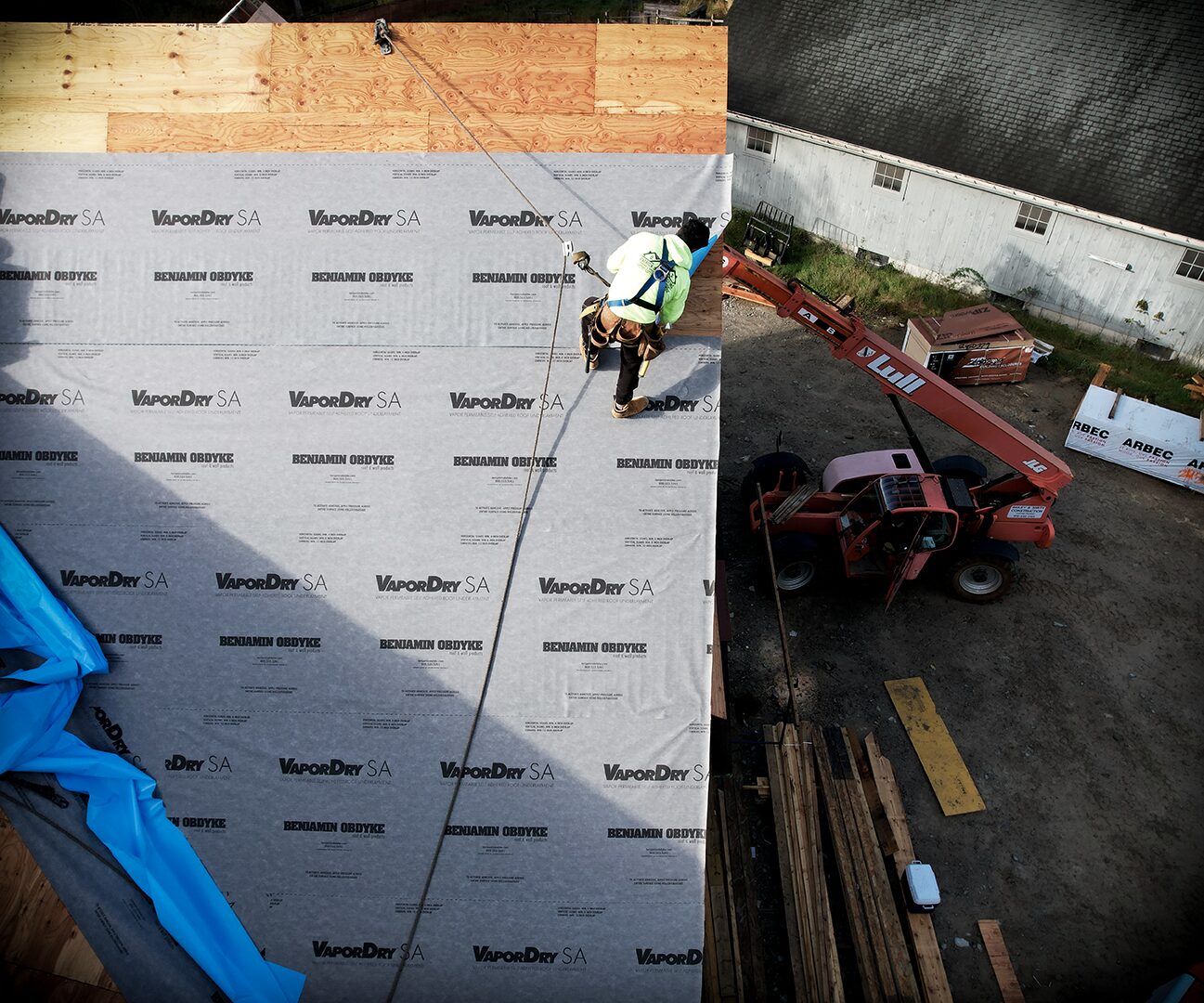

To learn more about the right rainscreen for your next project, schedule a virtual training session with Benjamin Obdyke experts.