Vertical open joint cladding is a popular choice for modern architectural designs. However, the typical application using cross-hatch furring strips in these installations can be both expensive and time-consuming. Learn how to achieve this desired aesthetic more efficiently while still protecting the building envelope.

What Makes Vertical Open-Joint Cladding Unique?

Open-joint cladding (OJC) has been trending for the past couple of years because it helps deliver a high-end, contemporary look that architects crave. Usually made with exotic hardwoods or composite decking planks, open-joint applications create deep shadow lines for a sophisticated look. While horizontal OJC is most common, vertical options are gaining popularity because of their distinct look that aligns with other design trends like board and batten.

Open-joint cladding creates a unique set of installation considerations, particularly from a moisture control standpoint. It essentially invites water behind the cladding material, so maintaining a consistent, effective water control layer is critical. Vertical OJC has these same concerns but also has additional challenges from a structural attachment standpoint.

Overcoming Structural Installation Challenges of Vertical Open-Joint Cladding

Whether an open-joint application or otherwise, any time you take panels and run them vertically, as opposed to horizontally, structural attachment becomes more difficult. Typical panel heights range from 4 to 6 inches, with lengths of 8 feet or more; these are easy to attach to studs in a horizontal application. But when you stand the panels on end for a vertical installation, 4 to 6 inches becomes the width over stud walls of 16 inches on center—so where do you attach?

Installers will need to plan ahead to install horizontal blocking or will need to increase the thickness of the exterior sheathing to provide an ample attachment point for the cladding fasteners.

Installation Options for Vertical Open-Joint Cladding

Along with structural considerations, it’s critical to plan ahead for moisture. With its greater exposure to the elements, open-joint cladding—horizontal or vertical—requires a permanent drainage plane behind it to allow bulk water to drain away and the cavity to dry out. The materials behind the open-joint siding also must be more resistant to UV rays than traditional options.

Cross-hatch, aka double strapping, is a potential solution that would eliminate the need for blocking or advanced framing, but it can be cumbersome, bulky, and time-consuming during installation. It also adds an additional thickness to the rainscreen, which can be a challenge to detail around windows and doors. Common furring strips of plain 1x wood aren’t ideal for long-term stability in the moisture-prone open-joint cladding application.

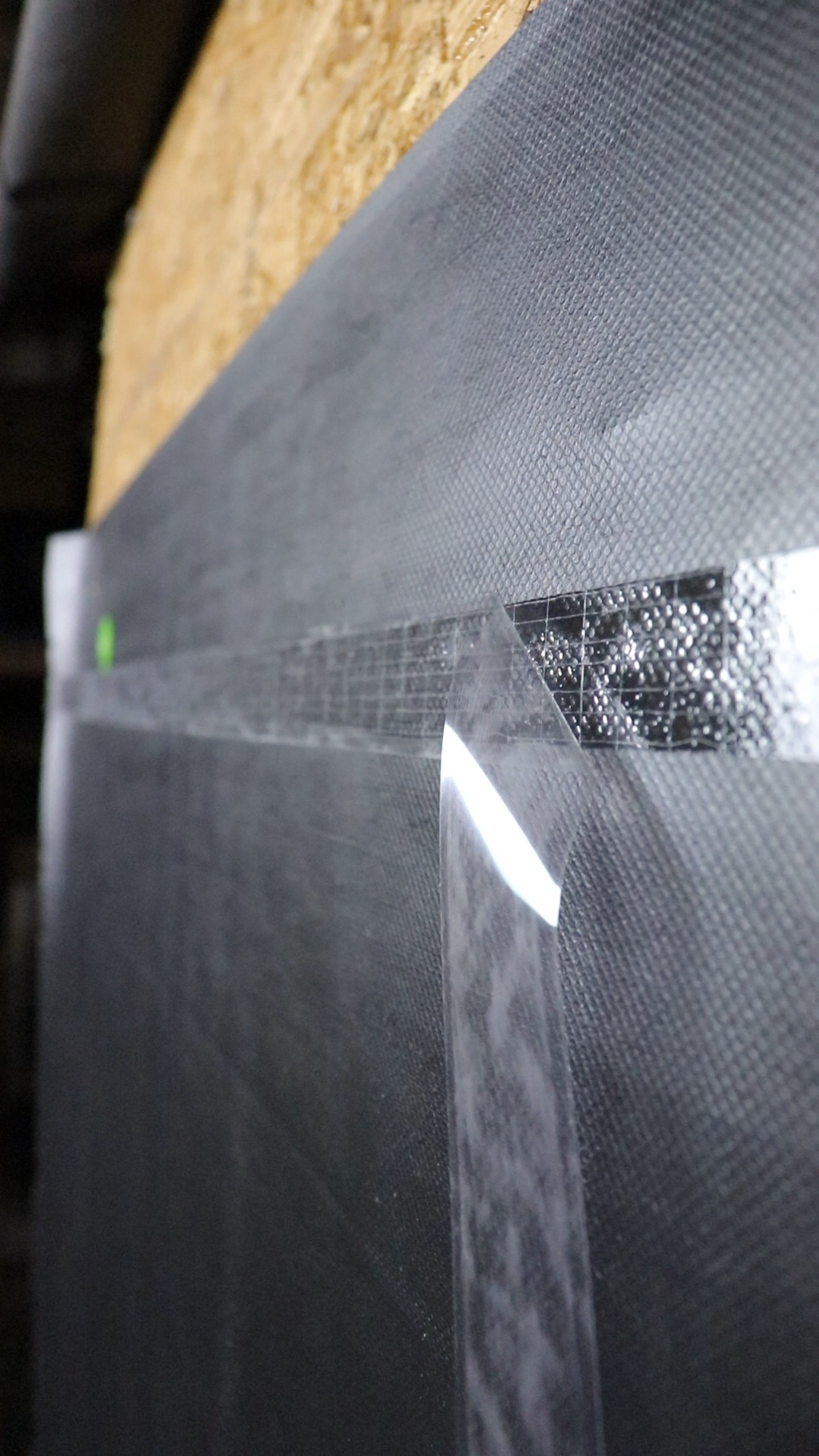

An easier option is to use Batten UV strips, if blocking is installed or the cladding manufacturer approves the attachment of cladding fasteners to the exterior sheathing. For this approach, select a structural-grade sheathing approved for the cladding and use InvisiWrap SA self-adhered housewrap, which offers UV resistance and a black color that helps preserve the aesthetics and shadow lines of the OJC.

Then, install Batten UV strips horizontally. Made with polypropylene and measuring 3/8-inch thick, the strips are UV stable and non-compressible, with notched edges to allow for moisture to drain down the wall; the open joints allow for airflow to assist in drying out.

Slotted attachment holes in the Batten UV strips provide for quick fastening while also allowing the product to expand and contract prior to cladding attachment; do not overtighten fasteners—leave at least a 3/8-inch gap to allow for the potential expansion and contraction. (As an added benefit, InvisiWrap SA is a self-adhered weather-resistive barrier, so it self-seals around the batten and cladding fasteners.)

Once Batten UV is applied, the cladding can then be installed directly to the battens and into the sheathing or blocking.

This approach using Batten UV provides the ideal combination of installation efficiency and moisture and UV protection for vertical open-joint cladding applications.

Want to learn more about installation options for open-joint cladding? Sign up for a virtual jobsite visit.