Roofing assemblies come with numerous intricacies, often leading to confusion surrounding their terminology and distinctions. Especially when it comes to cold roof and hot roof assemblies. So, let’s start with the basics.

Defining the Terminology

When it comes to understanding cold and hot roof assemblies, clarity is crucial. The terms themselves can be misleading without context. Typically, a cold roof assembly refers to a ventilated roofing system, where airflow is present somewhere within the roofing assembly. Conversely, a hot roof assembly is characterized by the absence of ventilation, creating an unvented roof system. Essentially, cold roof vs. hot roof also can be categorized as a vented vs. unvented roof assembly.

What Is a Cold Roof?

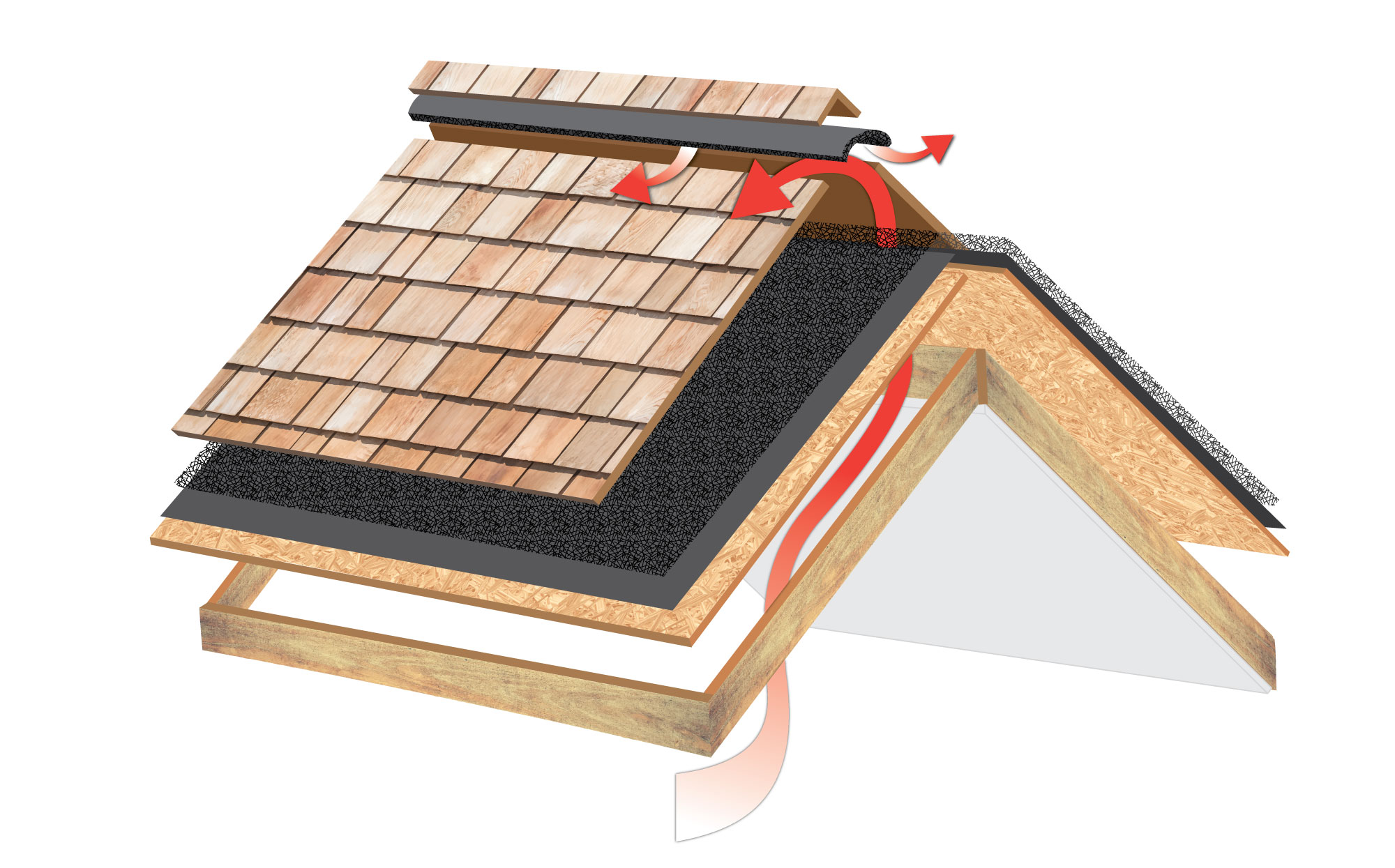

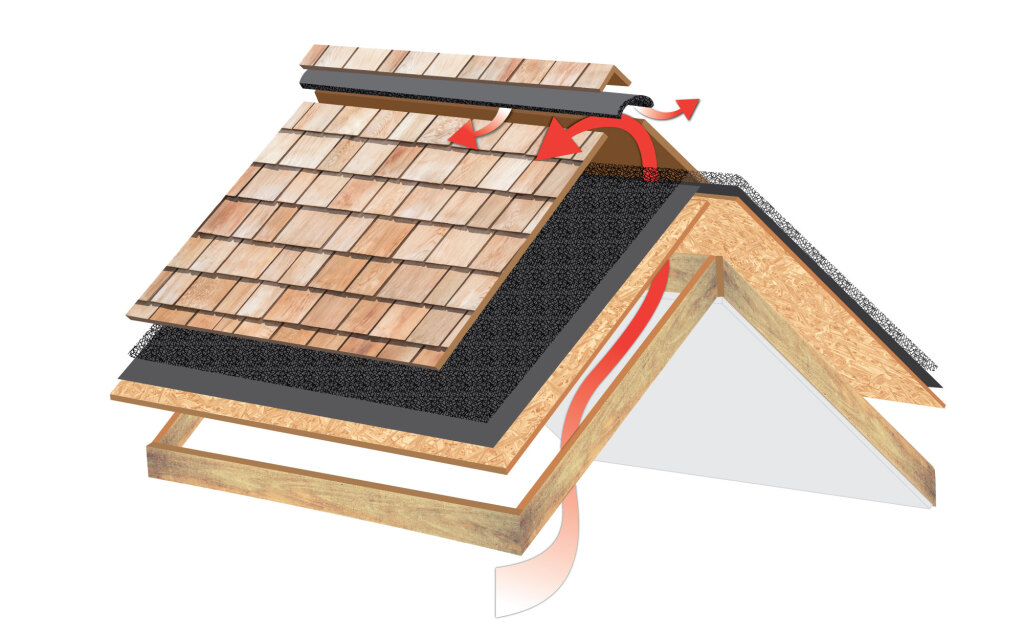

Traditionally, cold roof assemblies have been the norm. These setups feature ventilation, often through ridge vents and soffits, allowing airflow beneath the roof sheathing. It brings cool/dry air through the eaves and moves the hot/moist air up through the ridge vent. This airflow helps the roof sheathing maintain a colder temperature compared to the interior space, preventing issues like moisture buildup and condensation. Insulation is typically installed between the ceiling joists, creating a barrier between the interior space and the attic.

However, to get a better air barrier the industry is moving to a conditioned attic space. This relies on the mechanical/HVAC system to reduce the temperature and humidity of the attic, which can pose challenges in hot roof assemblies.

What Is a Hot Roof?

In contrast, hot roof assemblies forego ventilation in favor of increased insulation directly against the roof deck on the attic’s underside. Hot roof assemblies have grown in popularity due to their easy air sealing capabilities and the drive toward more energy efficient and net-zero homes.

This design maximizes energy efficiency by minimizing heat transfer between the interior and exterior environments. Spray foam insulation or other high-performance insulation materials are often used in hot roof assemblies, allowing for superior thermal performance and air tightness. However, the absence of ventilation raises concerns about moisture management and potential condensation issues, especially with conditioned attics.

Conditioned Attics

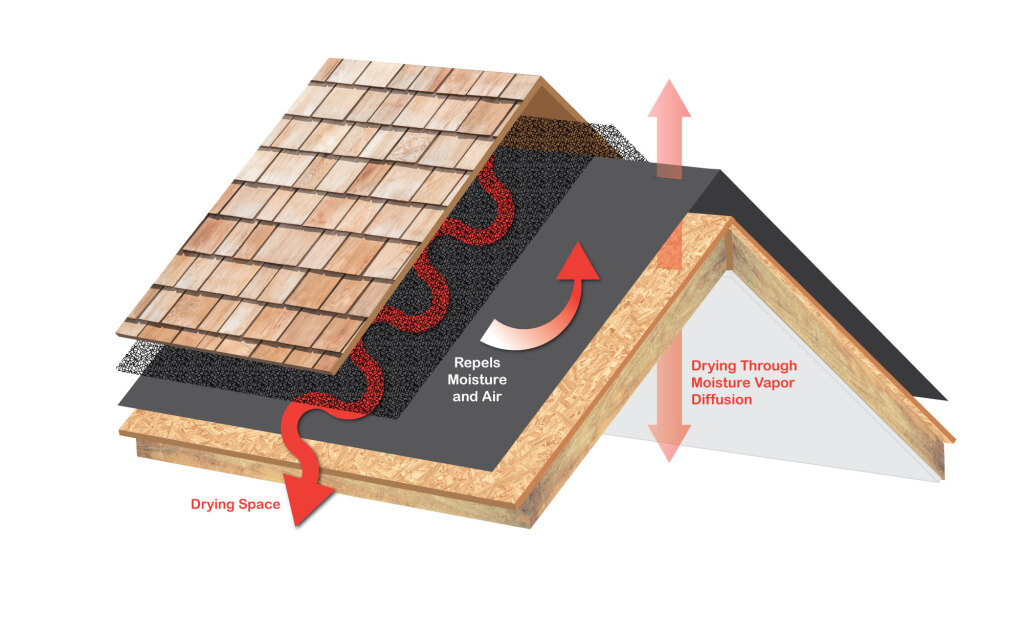

Conditioned attics are an increasingly popular option for homes to increase energy efficiency. Unfortunately, they often are not designed with proper vapor permeability nor adequate ventilation in mind, which can lead to condensation, mold and premature roof failure.

Challenges with Conditioned Attics

- The change from a vented to an unvented attic can trap vapor

- High vapor concentrations occur near the ridge

- Vapor-impermeable roof underlayments will prevent outward drying

How to Combat These Challenges

- Add a cold roof to a conditioned attic to reduce condensation risk

- Use a self-adhered, vapor permeable roof underlayment to maximize drying potential of the roof for both vented and unvented assemblies.

- Add both ventilation and a vapor permeable underlayment for best practice. For example, using Cedar Breather and VaporDry SA

- Consider a SIP (structural insulated panel) system, which highly benefits from an air-tight and vapor open underlayment

When to Use a Hot Roof vs. Cold Roof

The choice between cold and hot roof assemblies depends on various factors, including climate, location, building codes, and project requirements. In regions with hot and humid climates, hot roof assemblies are becoming increasingly popular due to their ability to minimize the influx of warm, moist air into the attic space, which can be more efficient for conditioned attic spaces. Though hot roof assemblies can enhance the efficiency of mechanical systems, they can increase the risk of moisture-related damage as well. Changing from vented to unvented roof assemblies requires a better understanding of vapor permeance on the roof sheathing. To learn more about vapor permeability, check out What to Know About Vapor Permeability in Roofing Systems.

VaporDry® SA Samples

GET YOUR FREE VAPORDRY® SA SAMPLES TODAY

The Role of Building Codes and Architectural Specifications

Architects and builders play a crucial role in determining whether a structure will have a cold or hot roof assembly. While building codes may offer flexibility in this regard, architectural specifications often dictate the preferred approach based on project requirements and performance goals. Remodeling projects may lean toward hot roof assemblies to maximize space and energy efficiency, while new constructions may consider various factors, including insulation and shingle type, ventilation strategies, and moisture management.

What’s Next?

As building technologies and construction practices shift, the nuances of cold and hot roof assemblies continue to evolve. Part 2 of this series will delve deeper into choosing the right roofing products for cold and hot roof assemblies, exploring factors such as underlayment selection, climate, and moisture control strategies.

Explore our resources for more ways to Build Better or get in contact with us today!