Across the building envelope, windows prove time and time again to be some of the most vulnerable areas and the most frequent points of failure. But it doesn’t have to be this way. Careful planning and detailing of the weather resistive barrier and window flashing using building science best practices and manufacturer recommendations can help protect the openings against moisture intrusion.

Part of those considerations pertain to the particulars of the window, including its material, shape, and size. Here’s what to consider when flashing different types of windows.

Does Window Material Matter When Choosing Flashing?

In general, what the window is made of doesn’t impact how you flash it — but it can influence what you flash it with. In selecting flashing, it’s important to ensure product compatibility with all other materials it will come into contact with. For example, some window manufacturers state that asphalt-based flashing tapes should not be used with their PVC nail flanges.

Along with the window itself, be aware of the flashing tape’s compatibility with the sealant used behind the nail flange. Some sealants can react with either the flashing tape, the weather resistive barrier, or the window components, including the paint or coating.

Flanged vs. Non-Flanged Windows

Windows typically fall into two basic categories — flanged (those with a nailing fin) or non-flanged (those without a nailing fin, often used for retrofit projects). But there are differences even within those two categories.

Flanged windows can be designed with integral or non-integral nail flanges, and this can impact the way it needs to be flashed. Windows with a non-integral nail flange may call for flashing onto the window frame, whether with a flashing tape, liquid-applied flashing, or a combination. Some window manufacturers also specify a double bead of sealant behind the nail flange.

A non-flanged window may rely on beads of sealant or liquid-applied flashing, and using a backer rod with the sealant is essential. Also, note that this detail can become more difficult to inspect if the unit is being pre-cased and requires the exterior sealant bead to be detailed from the interior.

Always refer to window installation instructions for specifics, including for details such as barrier versus drainage methods. Work with representatives from both your window manufacturer and your flashing manufacturer to determine the flashing methods that are most efficient, effective, and easily repeatable for your crew. There is more than one way to properly flash a window, but what may work for one crew may not work for another.

Specialty Shapes

Round or arched windows are notoriously tricky to flash, so look to a liquid-applied flashing like HydroFlash LA, which spreads easily around curves and other geometrically challenging areas. Straight flashing tape can be used, but may require a lot of cutting and trimming, making a liquid-applied option much more efficient.

How Exterior Insulation Can Impact Flashing

Another unique area to watch is window installations when the wall system includes continuous exterior insulation. The added thickness of the exterior foam boards puts the water control layer out of plane, which can make it challenging to create a continuous drainage plane and connect the water control layer with the window.

How you flash around an opening depends on whether it’s an “innie” window or an “outie” window. The innie window will need larger pieces of trim or metal to make up for the extra thickness. Depending on the window, it’s most straightforward to install the housewrap on the sheathing, in line with the window, and then use a traditional flashing application approach.

For an outie window, installers can add the weather resistive barrier on top of the foam, keeping the WRB layer and flashing detail in line with the window. At the bottom of the wall and other termination points, the flashing detail must be under the 2” of foam projection and onto the foundation.

HydroFlash LA is again an ideal option for these applications because, compared to straight flashing tapes, liquid-applied makes it easier to create a monolithic seal and be more precise when managing the more complex intersections and angles created by the exterior installation.

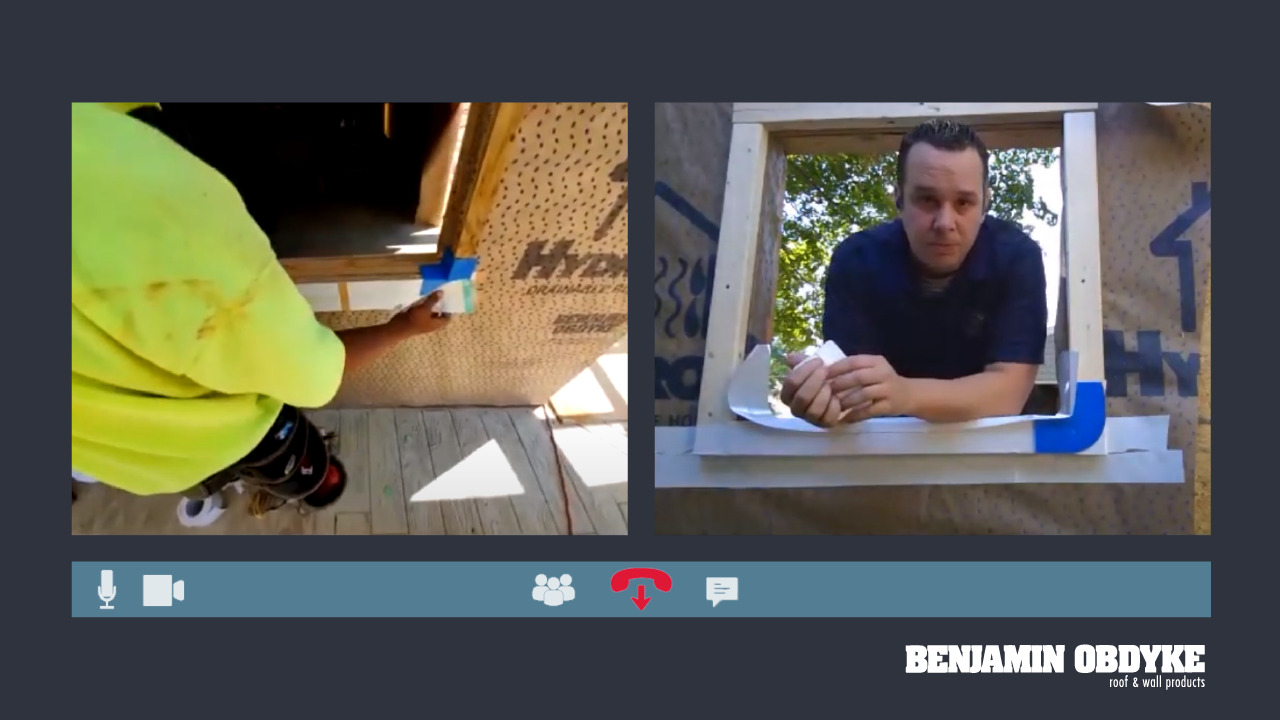

Support for Flashing Installation

Window flashing can feel intimidating, but your flashing and window manufacturers are here to help. Get started by scheduling a virtual jobsite visit today.