Building envelopes are one of the most common areas for a home’s failure. With so many variables, from climate to product compatibility to proper installation, there are many opportunities for water and air leakage to occur. In recent years, a focus on building science and a systems approach has builders thinking about the wall system in greater detail, helping to combat some of the historical woes of the envelope system.

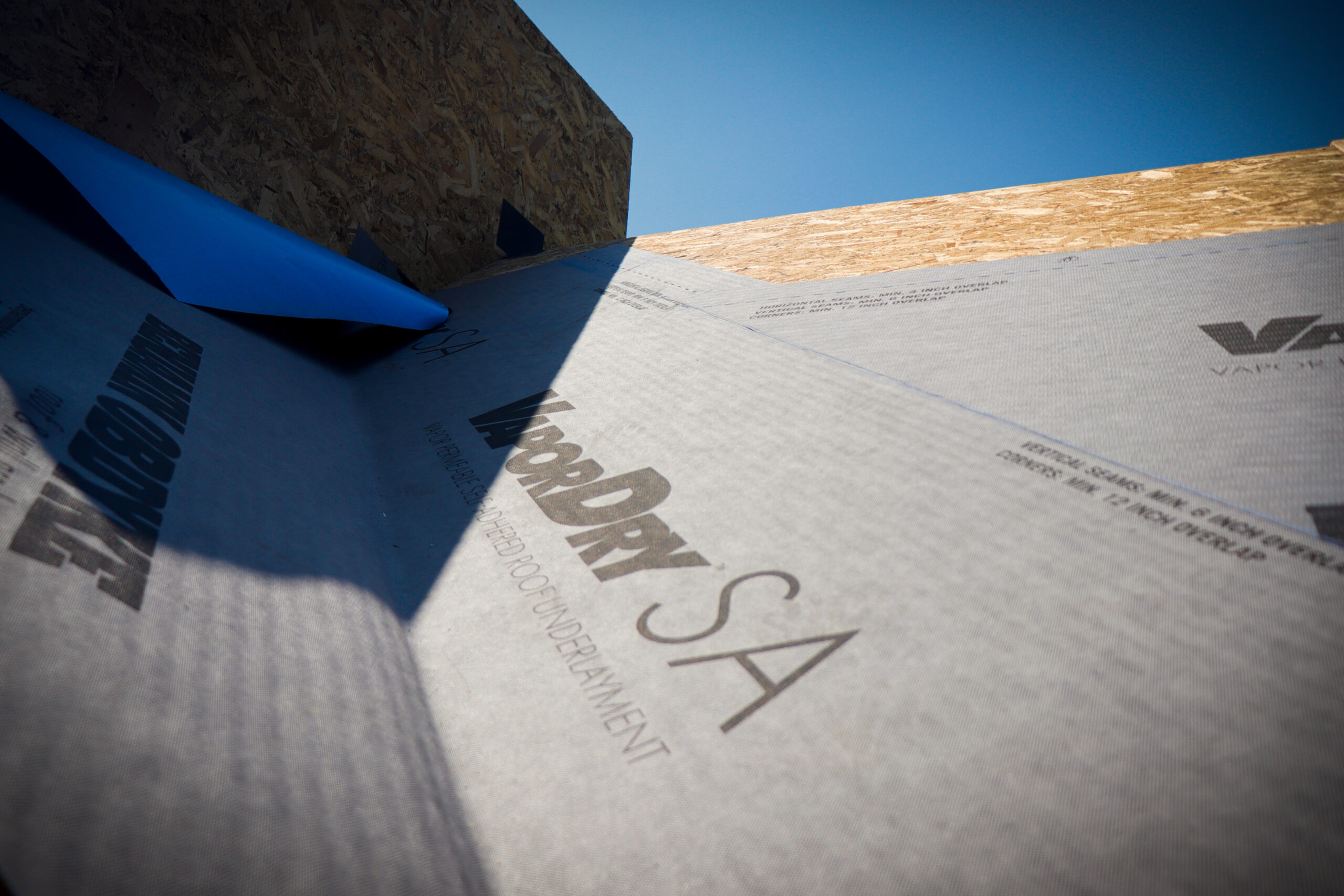

One of the most critical areas of the envelope is the housewrap. Choosing the right product for the application, planning its installation properly, and installing it correctly each play a crucial role in success.

Common Housewrap Failures

Though wall system failures can occur in a number of places, housewrap is the most visible element and also is one of the easiest areas to make positive changes that impact performance.

A common failure point for housewrap is the amount of penetrations through it—from the staples used to attach it as well as the siding nails that come after. The excess penetrations can lead to issues if moisture gets pulled through or when moisture trapped in the siding turns into vapor by the sun, pushing through the perforations.

A self-adhered housewrap such as HydroGap SA helps combat these potential issues by providing a continuous bond with the sheathing surface. Not only are housewrap staples eliminated, the adhesive will seal around the siding nail penetrations. With water and vapor blocked from the fastener holes, the wall system relies on the permeance of the housewrap, which in the case of HydroGap SA is a perm rating of 12.

In addition, HydroGap SA’s 1 mm spacers help water to drain away two times faster than traditional flat housewraps.

The 100% acrylic adhesive of HydroGap SA bonds with the substrate to prevent gaps that would allow moisture to collect. In contrast, if wind gets behind a mechanically fastened housewrap, water may get in and move throughout the sheathing layer.

The adhesive also helps prevent blow-off during construction, which is another challenge facing installers that can impact wall performance.

HydroGap SA can be used in combination with one of several flashing products (HydroCorner sill treatment, HydroFlash GP, HydroFlash LA, or HydroFlash UV+) to create the Air Barrier Drainable Housewrap System. Ideal for behind composite and fiber cement products, the system carries a 20-year warranty.

HydroGap SA Samples

GET YOUR FREE SAMPLES TODAY OF THE FIRST EVER SELF-ADHERED DRAINABLE HOUSEWRAP

Installation best practices

To fully take advantage of HydroGap SA’s tremendous sealing benefits, it’s important to use proper installation techniques. Critical areas include:

- Applying pressure: Once HydroGap SA is in place, use a floor squeegee, laminate roller, or dense push broom to apply firm pressure across the entire surface. Follow up with a firm squeegee to get out small wrinkles. This step is crucial to fully activating the adhesive and ensuring long-term adhesion.

- Utilize the split-release liner: HydroGap SA is designed with a split-release liner that allows installers to remove a portion of the liner, position the housewrap on flat areas and around corners, and then pull off the rest of the liner. This helps ensure proper placement and helps avoid the wrap sticking to itself as you negotiate wraparound points.

- Pre-plan: Before applying the housewrap, develop a strategic plan for the layout. On horizontal applications, use chalk lines to ensure the best bond and help avoid wrinkles. Pre-plan for how to navigate windows and other penetrations, including whether to use vertical application at certain points.

- Use two people: Self-adhered housewraps are best installed with more than one person to help ensure alignment and avoid the wrap sticking to itself or other things it shouldn’t, particularly on windy days. Have questions about installing HydroGap SA? Reach out to our experts here or give us a call at 800-523-5261.