Moisture is one of the biggest challenges for a wall system—and also one of the toughest to wrap your head around. One of the first steps is understanding how vapor operates, vapor perms, and the permeability of building materials through which it moves.

In our previous blog post, we explained the basics of vapor movement and vapor diffusion. Now let’s look at what vapor permeability ratings mean and how they will influence your design and installation decisions.

What Is a Vapor Perm Rating?

Just as it sounds, a vapor perm rating is the scale of measurement that rates the vapor permeability of a material—how effective it is at blocking or allowing water vapor to pass through.

There are four classes of vapor permeability, three of which are in direct correlation with the International Residential Code definitions for vapor retarder class.

• Vapor Impermeable (Class I): 0.1 or less

• Vapor Semi-impermeable (Class II): 0.1-1.0

• Vapor Semi-permeable (Class III): 1.0-10

• Vapor Permeable: greater than 10

What Determines the Right Perm Rating for a Building Envelope?

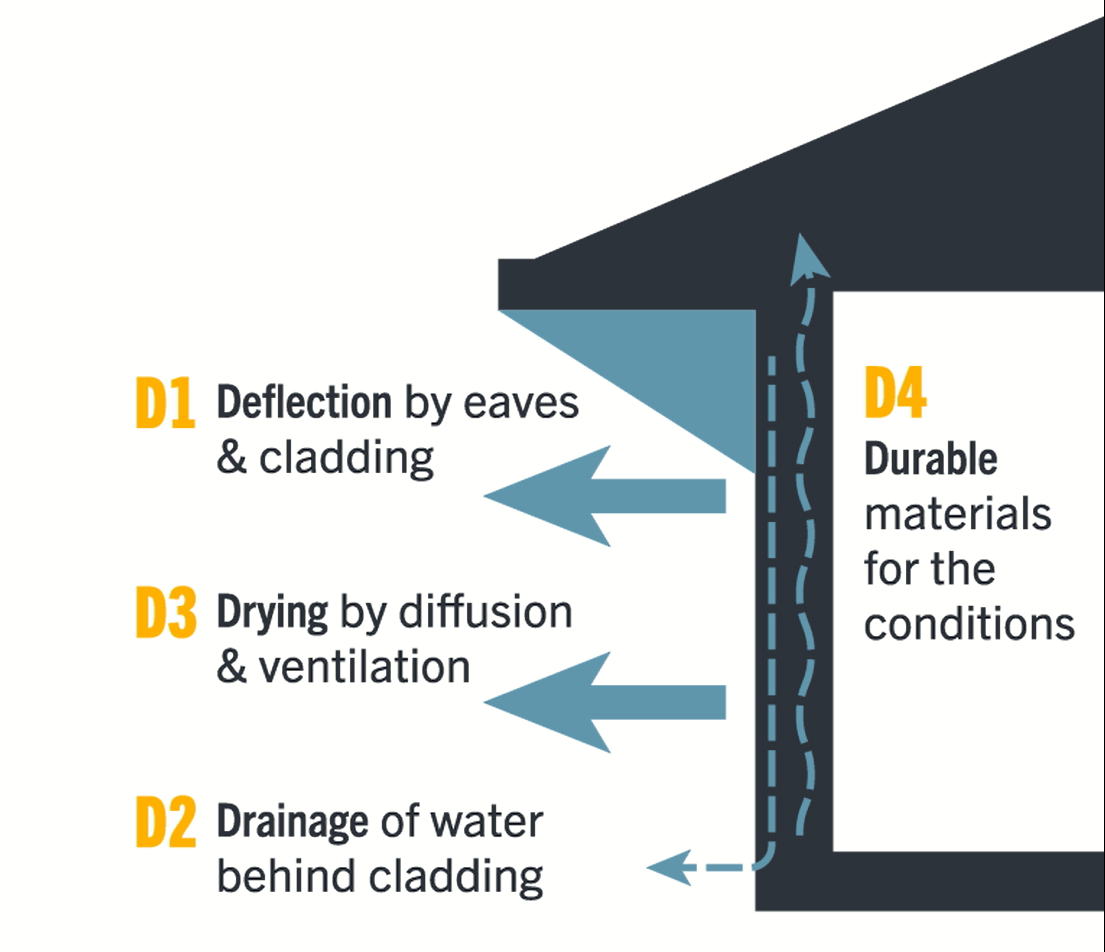

Unfortunately, there’s no one answer for what the preferred vapor permeability of an envelope should be, and it’s not code-prescribed from a whole-envelope perspective. Many factors come into play, particularly climate, and the whole wall must be looked at as a system. Code requirements dictate interior vapor control. In colder climates, a Class 2 vapor retarder will help prevent interior moisture from moving outward into the wall cavity.

For the entire wall envelope, the general guideline is for the assembly to be vapor open (i.e., not Class 1). The safest way to build is to allow water vapor to move freely through the assembly given seasonal changes in pressure—the higher the permeance in the wall assembly, the better the performance because it helps prevent trapped moisture. If something impedes the water vapor, it will stop the wall system from drying out.

Still, there is a sweet spot when it comes to choosing housewrap. Per code, the housewrap should be, at minimum, above 5 perms. Building science leans toward a range of 10 to 20 perms for the ideal balance. Greater permeability above 20 isn’t likely needed and may lead to issues—if the housewrap layer has an extremely high perm rating, such as 50 or greater, a wet wall may dry to the outside quicker, but in high humidity the vapor pressure will force moisture inward into the wall cavity. It’s a balancing act, and 10 to 20 perms will allow for drying while regulating exterior vapor pressure.

Beyond the housewrap, every material in the envelope has a different perm rating. The material with the lowest permeability is considered the “vapor throttle,” restricting movement and holding it longer. This is typically the OSB or plywood sheathing. That’s why having a housewrap that is vapor open, in the range of 10 to 20 perms, is crucial as it will help the sheathing dry out at a faster rate.

How Benjamin Obdyke Products Tackle Permeability Concerns

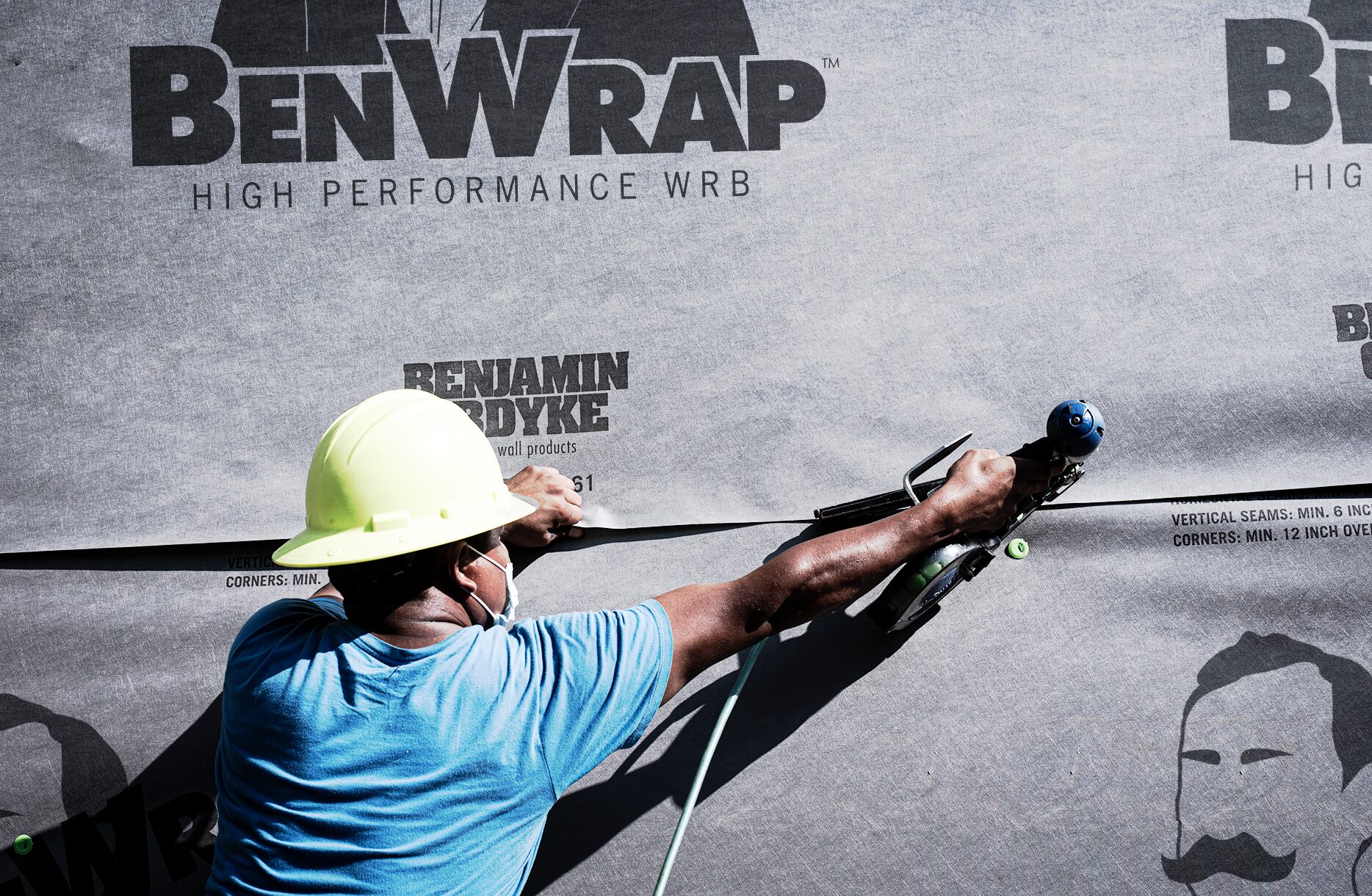

For exterior housewrap, all of Benjamin Obdyke’s products — HydroGap SA, HydroGap, InvisiWrap SA, InvisiWrap UV, and BenWrap — offer perm ratings in the ideal sweet spot of 10 to 20 perms, helping them meet the balanced needs for blocking moisture while allowing cavities to dry out.

For the interior, VaporWise vapor-variable membrane adapts to seasonal changes: During winter, VaporWise acts as a Class 2 vapor retarder, helping to prevent interior moisture from entering the wall cavity; in the summer, the membrane’s permeability increases, allowing moisture to escape and ensuring a dry, healthy wall cavity year-round.

Learn more about building science and Benjamin Obdyke products by scheduling a virtual jobsite visit today.