Rainscreens play a critical role in many building envelopes, creating a permanent space through which moisture can drain down and out of the wall cavity, and allow for air to move through convective air flow. There are a few important performance characteristics to consider when choosing a rainscreen, one of which is the product’s or material’s compression resistance, which is critical for its overall performance.

What Is Compression Resistance and Why Is It Important for Rainscreens?

The compression resistance of a rainscreen is the strength it has to maintain the cavity space against the applied pressure/compression during the installation of the cladding material. If a rainscreen is not compression resistant, the ventilation gap it creates can collapse under weight or force, typically from the fastener or nail, hampering airflow and drainage and ultimately leading to trapped moisture and reduced system lifespan.

Compression resistance is most critical when considering cladding types that are sharp, such as fiber cement. Compression resistance of the rainscreen underneath will help preserve consistent spacing as well as avoid creating a wave look along the expanse of the wall.

Compression resistance is measured in pounds per square foot, in accordance with ASTM D6364 standard. Compression is not regulated by codes, which only dictate the need for a space under certain cladding types, but is an important best-practice consideration to ensure optimal long-term performance of the wall system.

Which Rainscreen Options Are Ideal for Compression Resistance?

Pros have multiple options for rainscreens that reduce the concern of compression resistance. Traditional furring strips or Batten UV furring strips are naturally compression resistant. For rolled products, which create a complete drainage plane vs. furring strips, look for polypropylene-based materials, which have greater mass density, lending to greater compression strength.

Seek out information from your siding manufacturer about required or recommended rainscreens and rainscreen compression resistance.

In addition, it’s important that installers follow manufacturer instructions for psi settings on pneumatic nail guns and don’t set power drill torque too high, which could put unneeded additional pressure on the rainscreen. Hand-nailing is ideal.

High-Performance Rainscreen Options From Benjamin Obdyke

Depending on your project needs, Benjamin Obdyke offers several innovative rainscreen products that provide optimal drainage to eliminate the threat of trapped moisture in the wall cavity. This includes Batten UV furring strips, Slicker Classic, and Slicker Max.

Slicker® Rainscreen Samples

GET YOUR FREE SLICKER® RAINSCREEN SAMPLES TODAY

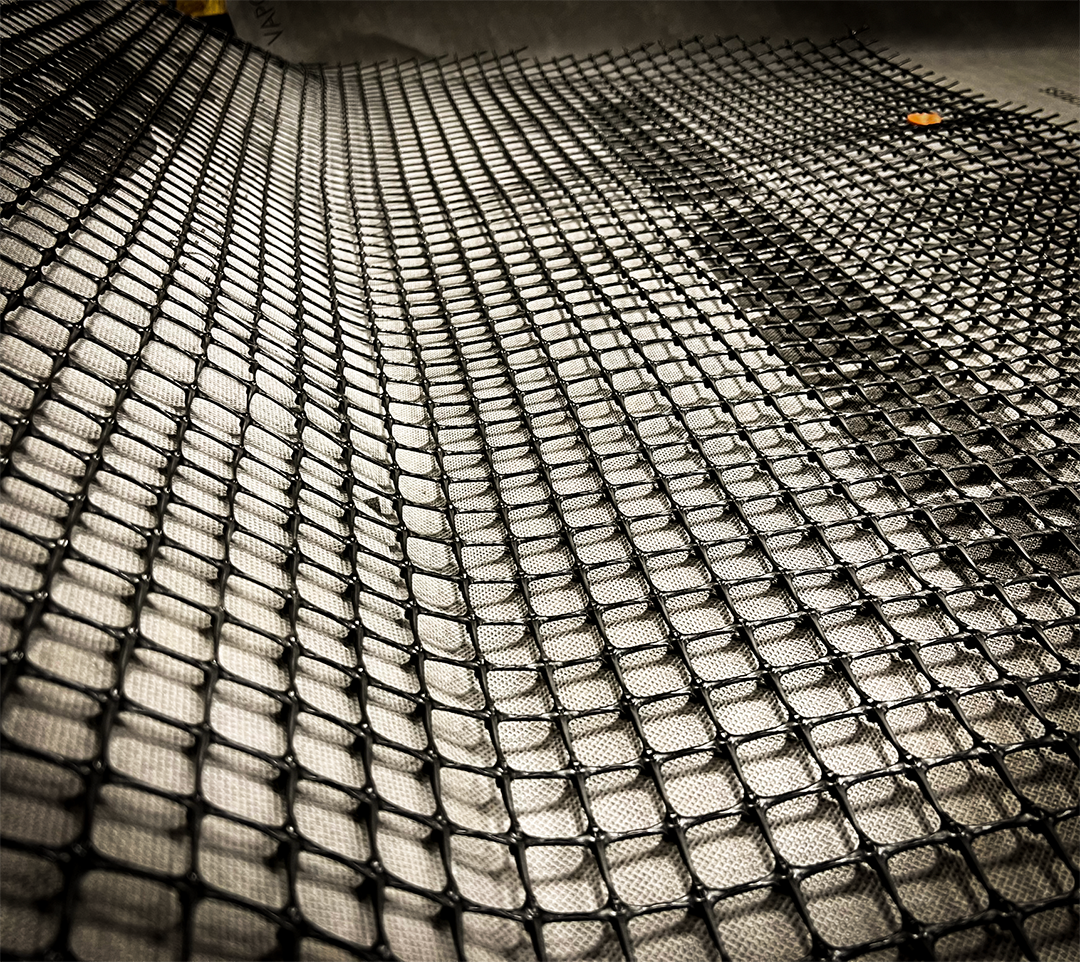

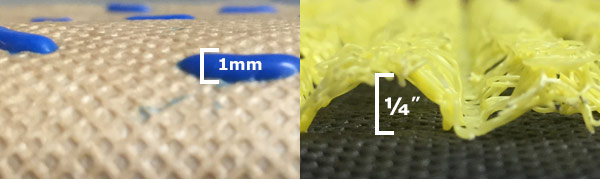

For the ultimate in compression resistance, look to the new AeroNet Wall & Roof Ventilation Mat, which will be available nationwide in the coming months. AeroNet combines the installation benefits of a rolled rainscreen with the compression resistance of a grid/mat system. It features a lightweight, flexible design and fastens with cap nails or staples—no special tools required.

Ready to learn more about the right rainscreen for your project needs? Schedule a virtual jobsite visit today!