As a builder or contractor, it’s crucial to strike a balance between adhering to recommended standards and how they apply in real-world applications. ASTM standards align with the building codes and are a great resource for ensuring the safety and performance of the homes you build. These standards, developed by consensus, aim to protect homeowners and end users while enhancing quality of life. It goes back to the fundamental reason why we build—to create safe and habitable spaces for people to live and thrive.

Still, it’s important to understand what the tests indicate—and what they do not—when weighing them alongside other product characteristics.

The Benefits – and Limitations – of ASTM Standards

ASTM standards serve as the fundamental framework for assembling structures, ensuring the creation of safe and healthy buildings. As contractors, manufacturers, architects, and builders, it is our responsibility to take that basic information and understand how different materials work together to create a high-performance building assembly. Although ASTM tests are the standard, we’ve seen you can go beyond that to get better performance in real-world situations.

Every standard is unique. Let’s get technical and break down the relevant standards for the building envelope, along with their importance and limitations.

ASTM E96

ASTM E96 focuses on vapor permeance and is used throughout many industries to understand how much water vapor can pass through a solid object. It provides a standard for how manufacturers test the vapor transmission of their materials; this allows you as the buyer or specifier to make accurate comparisons and know that products meeting ASTM E96 have been tested in accordance with third-party requirements.

With every test standard, you need to balance it with education and a proactive approach. And with this one, we must look beyond just meeting the standard to understanding the permeability ratings of all the different layers—sheathing, insulation, flashing, houswerap—and how they create the overall vapor permeance of the wall assembly. This is critical because the wall assembly is never tested in completion for vapor permeance; it’s knowing that each layer has its own and how that funnels down vapor movement through the wall.

For example, weather-resistive barriers ideally should have a perm rating between 10 and 20, which provides a balance between preventing excess moisture from coming in but not too low that it can’t move out.

ASTM E2273

ASTM E2273 is the standard test method for determining the drainage efficiency of EIFS clad wall assemblies. This standard came to be because of failures in the EIFS installations in the 90s.

One of the limitations of ASTM E2273 is the test method used to determine performance. The test involves a 4-foot-by 8-foot sheet of plexiglass put over a housewrap, with water draining down in between. However, the plexiglass is an impervious material, but most claddings we use, whether fiber cement or a natural wood product, absorb water.

Another caveat is the test does not look at the time it takes for water to drain down and out of the wall. If it takes an hour, in real-world applications a lot of that water would be absorbed into the cladding, causing it to deteriorate over time. Trapped moisture will sit there and stress the flashing details, fasteners, staples, siding nails, and anything penetrating the WRB.

A product like HydroGap, which has a built-in 1-millimeter drainage space, allows water to drain down and out of the wall system faster, helping to prevent the cladding from absorbing moisture. It is important to note that while flat housewraps may pass ASTM E2273, this does not provide a comprehensive understanding of the membrane itself; during the test, flat housewrap has large cap fasteners butting the piece of plexiglass, creating a space for drainage during the test while not reflecting the amount of time it takes for that water to drain out, just that it does. That is why it is vital to look at both the time to drain and the drainage efficiency of your wall envelope. Read Get the Whole Story: Drainage Efficiency and Time to Drain to better understand the impact it can have on your assembly.

ASTM D1970

A popular test standard used for the roof system is D1970—this is for the ice and water shield self-adhered roofing underlayment but is limited to asphalt-based adhesives. As we move forward in the industry and new products and technologies emerge, like our acrylic-based VaporDry SA, D1970 is rendered irrelevant because of the different characteristics between the two types of adhesives.

This requires us to look at alternative test standards that recently came through the International Code Council (ICC). They realized materials were changing and developed AC48. This AC48 code, designed for synthetic underlayments, is a stringent test standard that is more extensive than D1970 concerning UV exposure, strength, and other components.

VaporDry® SA Samples

GET YOUR FREE VAPORDRY® SA SAMPLES TODAY

Navigating ASTM Standards and Real-World Applications

To strike a balance between ASTM standards and real-world relevance, we must understand what those standards cover and don’t cover as well as the real-world application of the products. We need to recognize that these test standards have strict, controlled testing environments.

But jobsites are unpredictable, from extreme temperatures to installers who aren’t up to date on best practices. So, the recommended approach as a professional is to take these tests and evaluate how they apply to each project.

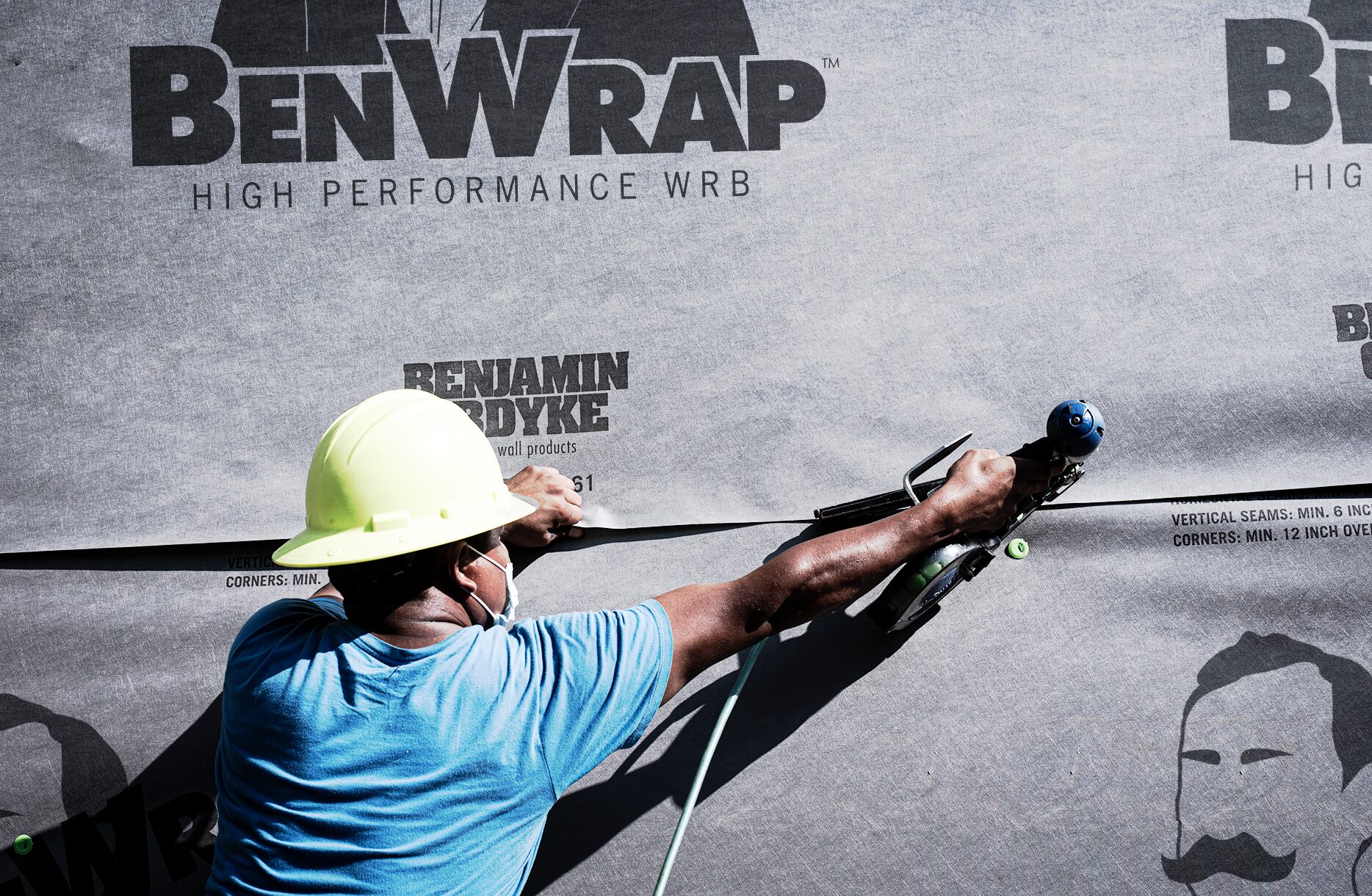

We always encourage contractors to put our products through the ringer. Stick the adhesives to different surfaces on the jobsite, try to rip the products off the wall, and pour water down the wall after the cladding installation to see how quickly it drains. Whenever we look at a product, we need to understand both its benefits and its limitations. By leveraging ASTM standards, we establish a benchmark for evaluating different products, then seamlessly transition into practical insights on real-world installation, with the knowledge we need to go a step beyond that to achieve high performance.

Want help to navigate these standards or tips for the jobsite, contact us today!