When considering steep-pitched roof systems, we often think about how weather and climate factors impact the roof itself. But what’s underneath—and how the entire system works together—also plays a key role in dealing with environmental challenges.

Roofing underlayment acts as a second layer of defense for the roof, preventing water intrusion from wind-driven rain, helping to reduce air infiltration, and protecting the structure prior to roofing installation. Underlayment is an essential component in helping the roofing system resist external environmental forces that can wreak havoc on the building envelope and the home’s overall durability and performance.

Environmental Forces Acting on a Steep-Pitched Roof

The roofing system faces five main environmental challenges—bulk water, extreme heat, extreme cold, high winds, and vapor diffusion—and the proper underlayment, ventilation, and flashing details can help the system protect against each of these.

Bulk Water on the Roof

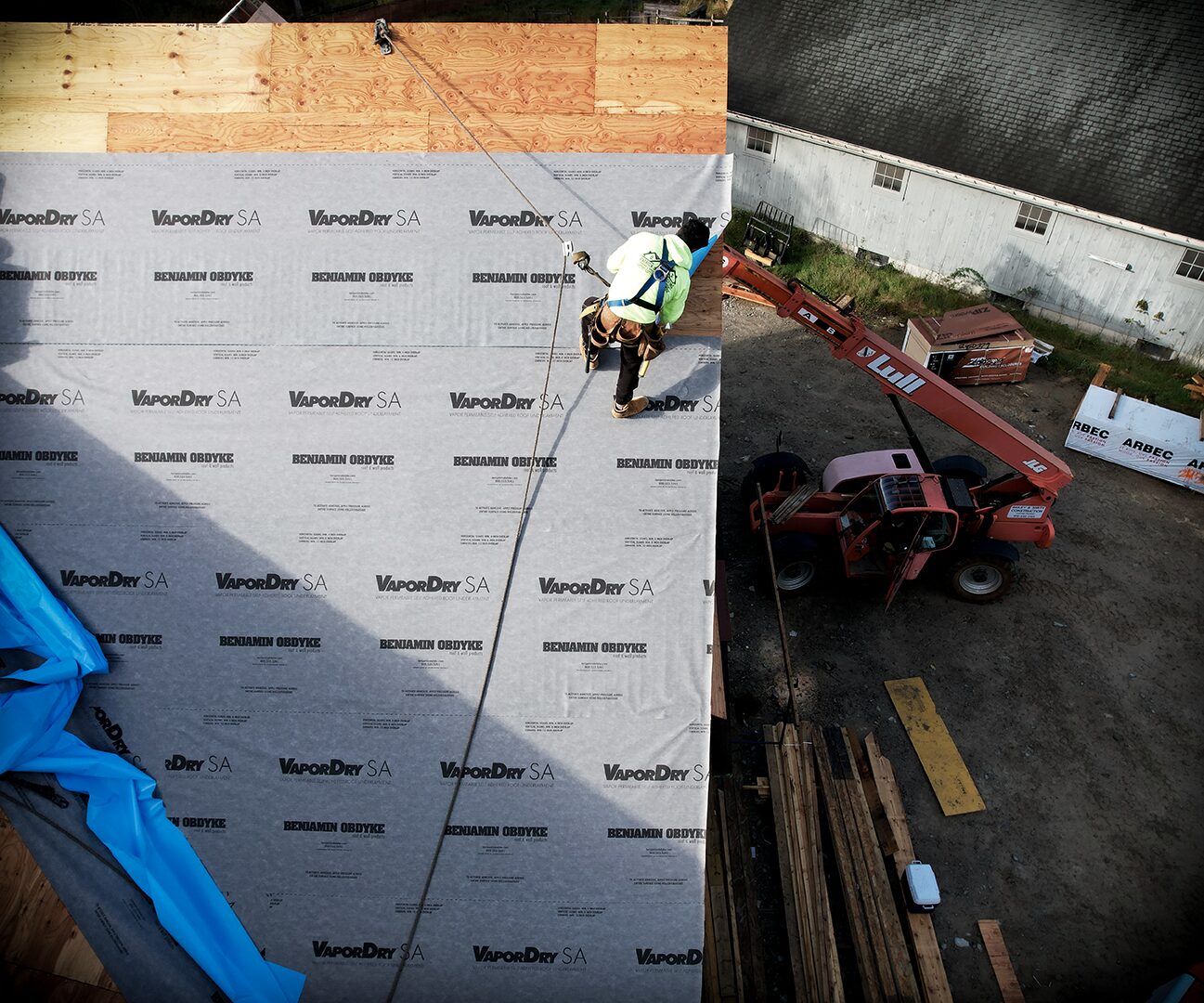

A 4-foot section of roof must handle about 70 gallons of water per year from rain and snow. A steep-pitched roof is designed to shed water, but it is not waterproof. Therefore, underlayment, in combination with proper flashing details, is a critical last line of defense. Installers also should reduce roof penetrations as much as possible. A self-adhered underlayment such as Benjamin Obdyke’s VaporDry SA will self-seal around fasteners.

VaporDry® SA Samples

GET YOUR FREE VAPORDRY® SA SAMPLES TODAY

Extreme Heat and the Roof

The roof bears the brunt of the home’s sun exposure, and as such can reach temperatures as high as 120 F to 180 F during summer months. The different parts of the roof system need to work together to address this stress: materials must be designed to expand and contract with large temperature swings. Roofing selection (material composition and color) can help reduce maximum roof temperature, along with ventilation strategies that can help dissipate heat and moisture from the assembly.

Extreme Cold

It’s important to consider the home’s climate when choosing roofing materials; for example, asphaltic materials may become brittle when temperatures drop near freezing. The materials underneath the shingles or panels also are vital to control the moisture risks that can arise—using asphalt-based underlayments may increase the chances of moisture-related failures. Proper ventilation is important, as large temperature differences between outside and inside can create and trap condensation; poor air control and thermal resistance can lead to ice damming at eaves and valleys, and this buildup of snow and ice can drive water under the shingles.

High Winds’ Impact on the Roof

Shingle blow-off isn’t the only concern when it comes to roofs. Strong air currents can stress the roof design, and wind-driven rain can move up the roof pitch and test flashing and transition details. Using a self-adhered underlayment can help protect the structure if the roofing is damaged. In addition, unvented roof assemblies with a continuous air barrier can resist high-pressure differences.

Vapor Diffusion

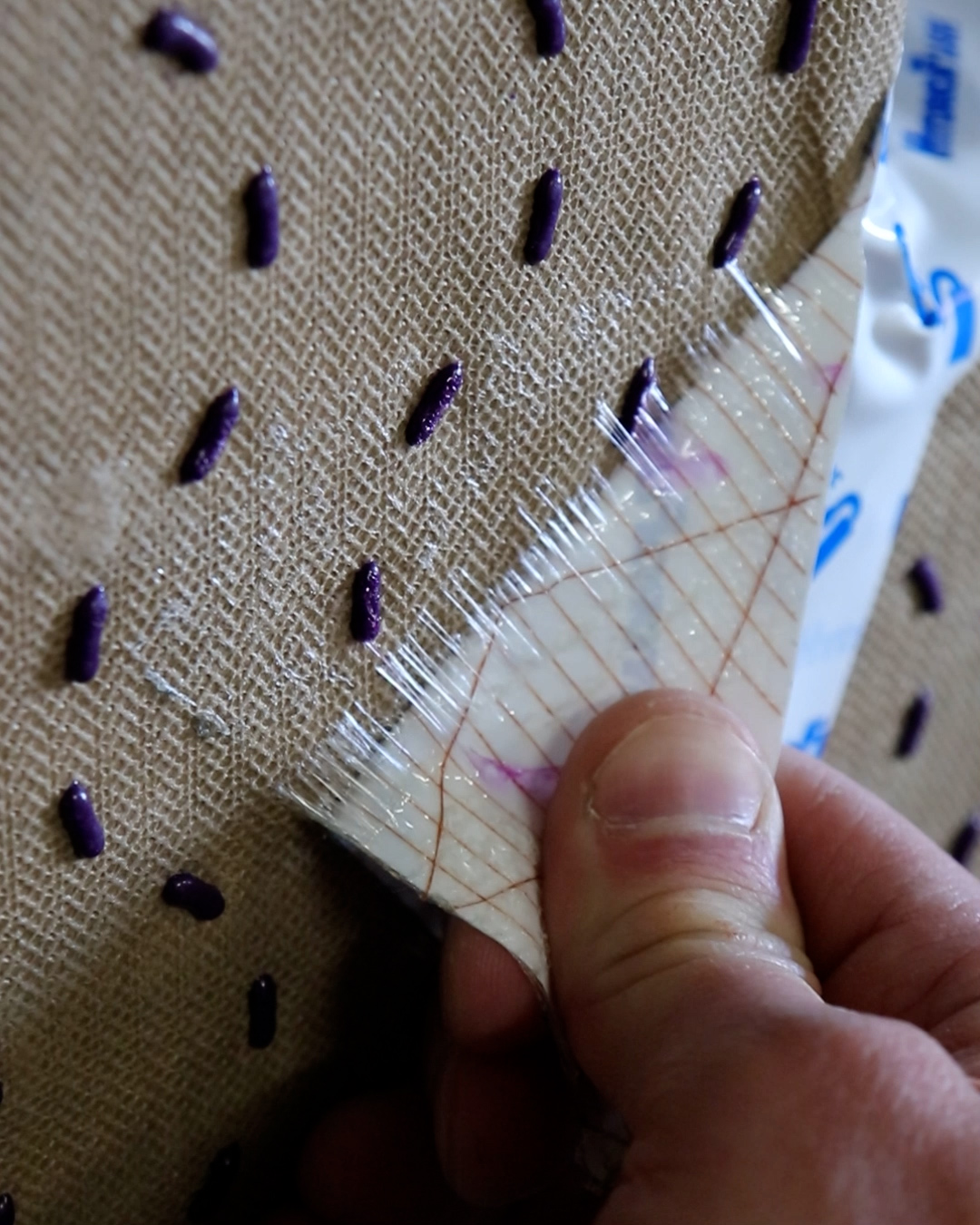

Vapor diffusion is the environmental force that impacts the roofing system from inside the home—it’s also the hardest to see. Vapor diffusion can occur when attics are conditioned and unvented, which increases condensation risk. Vapor barriers like closed-cell spray foam prevent drying potential if vapor enters the assembly, further exacerbating the problem. Interior vapor retarders can reduce the risk if installed continuously, but an easier solution is a vapor permeable roofing underlayment such as VaporDry SA.

Designing to Resist Environmental Forces

Designing the roof as a system, one that considers proper ventilation, underlayment, flashing, and detailing based on the roofing materials, climate, attic space, and other factors, is crucial to building a home that is protected from exterior and interior forces.

In our CEU course “Durability for Steep-Pitched Roof Assemblies,” we expand on this content in more detail as well as address how to design and specify systems for these elements, how to detail common failure locations, and understand code compliance. To sign up for the course, click here.