The design aesthetic of open-joint cladding systems has made it a popular choice among architects and homeowners alike in North America. Unlike a conventional wall system, these façades allow air, water, and sun to enter the building envelope. While the open space is beneficial because wind naturally carries moisture out from behind the cladding, it can pose some challenges. The gaps between the boards cause the building envelope to be exposed to increased moisture and UV rays.

Building science has taught us that moisture is the number one reason building envelopes fail. Because of this, many decking and cladding manufacturers have certain requirements for the moisture control layer used in conjunction with their products.

Breaking Down the Requirements

Over the last five years we’ve worked with decking manufacturers who are entering the open-joint cladding arena to understand their requirements. One of the most important specifications to make notice of is the call out of a code complaint, UV stable weather-resistant barrier that can provide bulk water drainage. Before we jump into the specifics required by the decking manufacturers, be sure to check out this blog where we discuss everything you need to know about open-joint cladding.

See what some decking manufacturers require help to ensure longevity, aesthetics and protection of your project:

Trex

- Furring strips that are pressure-treated wood or 18 ga. steel

- Water-resistive UV-stable, vapor-permeable membrane that is code compliant

- Must be installed as a rainscreen system

Fiberon

- Furring strips that consist of metal, wood or PVC boards, entangled nets with or without fabric, corrugated plastics, and other products that meet or exceed the design requirements

- Weather-resistive barrier (WRB) that meets needs for UV stability, water resistance, moisture infiltration and water vapor exfiltration and is code compliant

- Must be installed as a rainscreen assembly

Azek

- Furring strips that are 2×4 pressure treated with approved fastener options – paint the furring strips a dark color to minimize their view.

- Weather-resistive barrier that is code compliant and best suited for the project

- Must be installed as a rainscreen assembly

Envision

- Furring strips that are structural in nature and pressure treated wood or other exterior grade structural material

- Water-resistive barrier that is black in color, rated for UV Exposure and code compliant

- Must be installed as a rainscreen or vented application

See how Benjamin Obdyke products can help you meet these requirements:

How Our Products Fill the Gap (Literally)

We’ve manufactured a fully comprehensive, UV-rated Open-Joint Cladding System that includes InvisiWrap UV, HydroFlash UV+ and Batten UV. All of these products can be exposed to direct UV light for 12 months before cladding is installed. Let us break down the details:

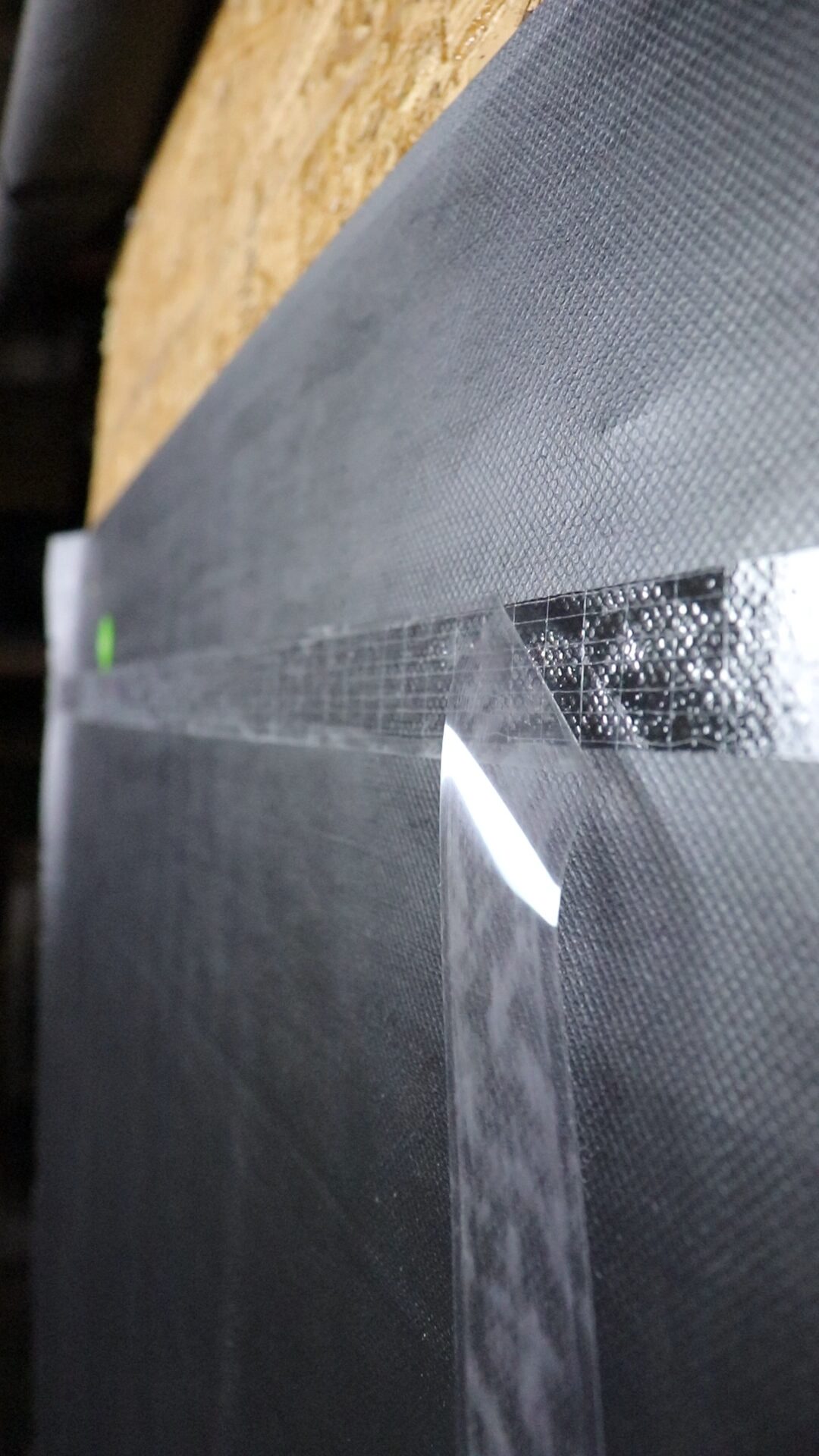

InvisiWrap UV, our UV-rated housewrap is specifically designed for these types of projects. It exceeds the requirements of AC 38 and has a vapor permeance of 14. Taping the seams of the wrap is also a critical step in the installation process to best control the amount of vapor moving in and out of the cavity.

Our tape, HydroFlash® UV+, is formulated with an acrylic adhesive for extreme environmental conditions with a vapor permeance of 4 which allows drying to the exterior.

When the housewrap and tape are used in conjunction with Batten UV Rainscreen, the system ensures water can cascade down and out of the wall cavity while providing superior water holdout and bulk water drainage.

The high permeability of the wrap allows for excess moisture to escape, the low permeability of the tape prevents excess water vapor from moving in and the rainscreen creates that mandated space for drying and drainage required by manufacturers.

Ensure your open-joint cladding system is protected from rot, mold and fungus, and looks aesthetically pleasing. Learn more about our specialty designed system for moisture control in open-joint cladding.