If you’re a building products connoisseur, you’re likely familiar with self-adhered membranes. These materials have been around for over a decade; however, in recent years, the performance of these products has grown by leaps and bounds.

So just what does a self-adhered weather-resistive barrier (WRB) offer?

An Evolution to the Building Envelope

Self-adhered WRBs have become a fan favorite among builders nationwide, especially over the last few years. These products have evolved tremendously since their introduction to the building industry, with the performance around air control setting them apart from their mechanically fastened counterparts.

With the criteria of these products increasing, we’re able to build better building envelopes that are high-performance, more sustainable, and reduce energy consumption. These benefits are significant in the residential sector, where we’ve seen increased use of self-adhered WRBs. From an air-sealing perspective, a self-adhered WRB creates a permanent bond with the sheathing surface, which protects against hydrostatic pressure and water intrusion.

If you’re looking to build a higher-performing building envelope, it might make the most sense to use a self-adhered WRB. You should also use this type of product in projects where the exterior sheathing acts as the air control layer.

All About the Acrylic Adhesive

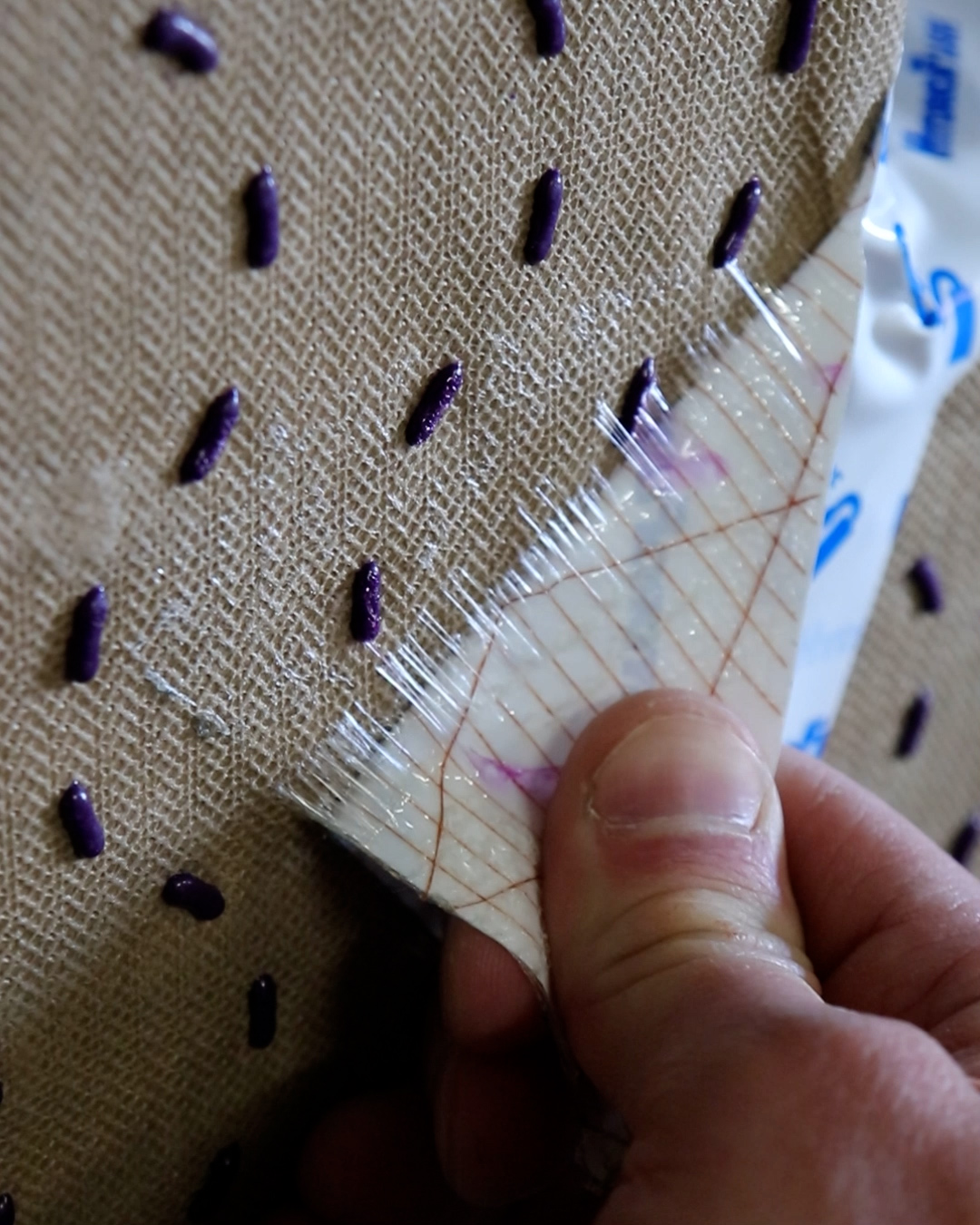

Part of the evolution of self-adhered weather-resistive barriers is the introduction of new adhesive technologies. Benjamin Obdyke uses a 100% fully continuous acrylic adhesive on our self-adhered WRBs, which boasts many benefits. An acrylic-backed housewrap is repositionable, providing the installer with more flexibility if initial placement isn’t perfect. Additionally, the acrylic adhesive can be easily separated, so there is less worry of material waste or damage if it gets stuck together. Regarding air sealing details, acrylic adhesive seals around any fasteners or penetration points in the WRB, ensuring the air control layer remains unaffected.

The key to successfully performance of a self-adhered WRB comes down to the installation. To learn more about installing a self-adhered housewrap compared to a mechanically fastened housewrap, check out our previous article.

HydroGap SA Samples

GET YOUR FREE SAMPLES TODAY OF THE FIRST EVER SELF-ADHERED DRAINABLE HOUSEWRAP

The Future of Self-Adhered WRBs

If you’ve yet to make the switch to a self-adhered WRB, there’s no better time to do so. With building codes beginning to place more importance on air sealing, specifically low air change numbers, a self-adhered membrane for your wall system may soon become a go-to product in your toolbox.

Once you’ve gotten your hands on the right product and used it a time or two, you’ll undoubtedly start to see the benefits and understand why they’re crucial.

We’ve got two popular self-adhered wall products in our lineup:

HydroGap SA – The first self-adhered WRB to incorporate a true drainage space.

InvisiWrap SA – A durable and high-performance black housewrap with increased UV protection for open-joint cladding or light commercial projects.

Properly using a product is the first step, and we’re here to help you do just that. If you’re interested in talking to one of our experts, please get in touch!